Pioneer Oil Refinery - Refining the Oil

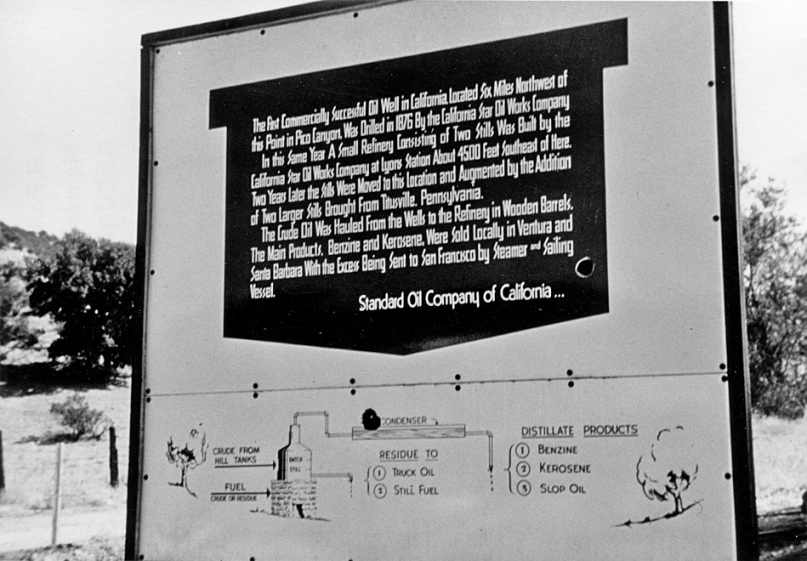

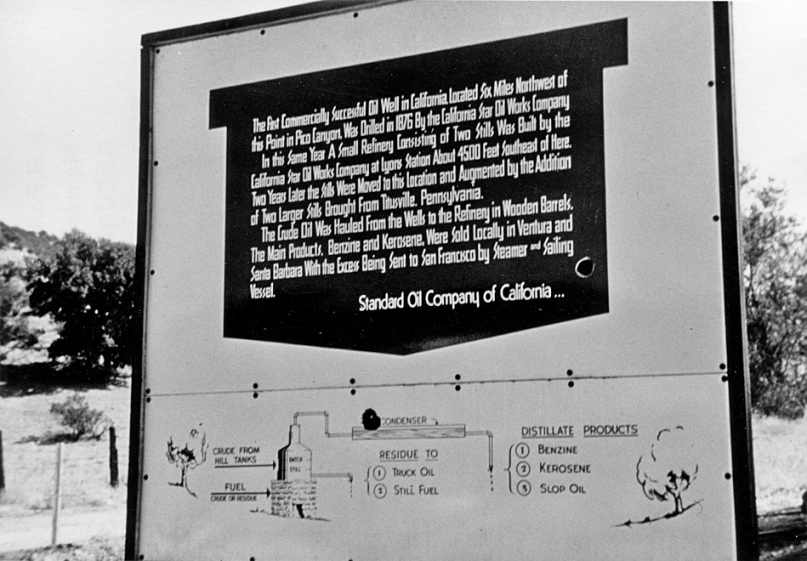

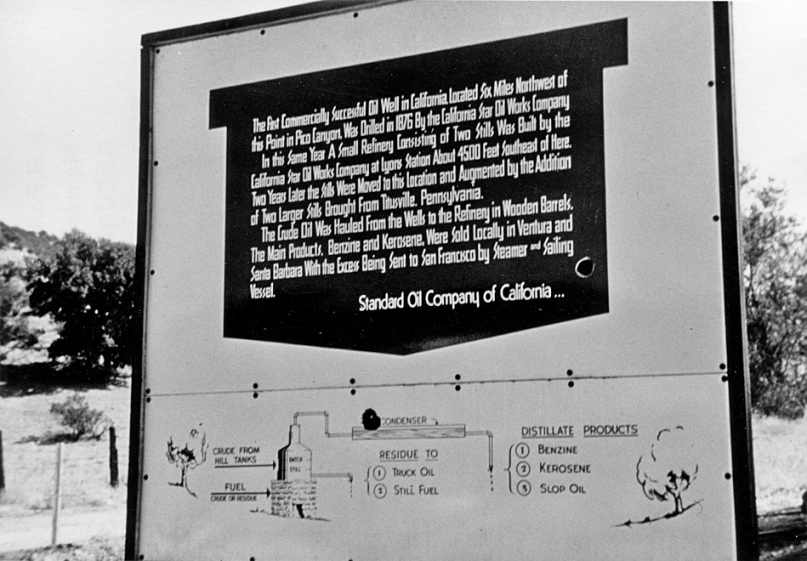

Sign in front of the stills showing a simplified explanation of how the refinery worked. Today, the sign is unreadable. (Photo by Arthur B. Perkins)

"The first commercially successful oil well in California, located six miles northwest of

this point in Pico Canyon, was drilled in 1876 by the California Star Oil Works Company.

In this same year a small refinery consisting of two stills was built by the

California Star Oil Works Company at Lyons Station about 4500 feet southeast of here.

Two years later the stills were moved to this location and augmented by the addition

of two larger stills brought from Titusville, Pennsylvania.

The crude oil was hauled from the wells to the refinery in wooden barrels.

The main products, benzine and kerosene, were sold locally in Ventura and

Santa Barbara with the excess being sent to San Francisco by steamer and sailing

vessel.

Standard Oil Company of California..."

Copyright Note: This image is NOT in the public domain and was used by permission of the SCVHistory website.

Refining of crude oil was done to get rid of smoke, smell, and to make it non-explosive, when used for illumination purposes.

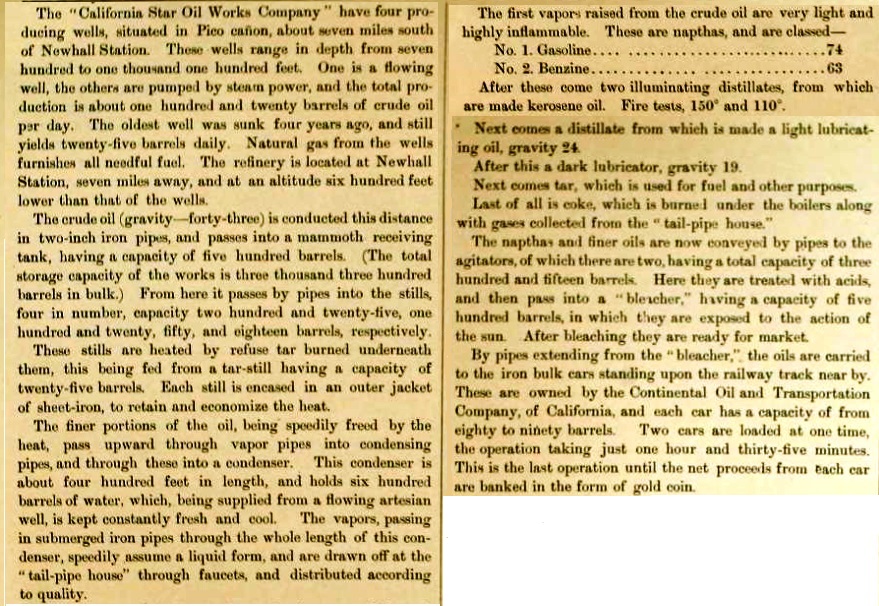

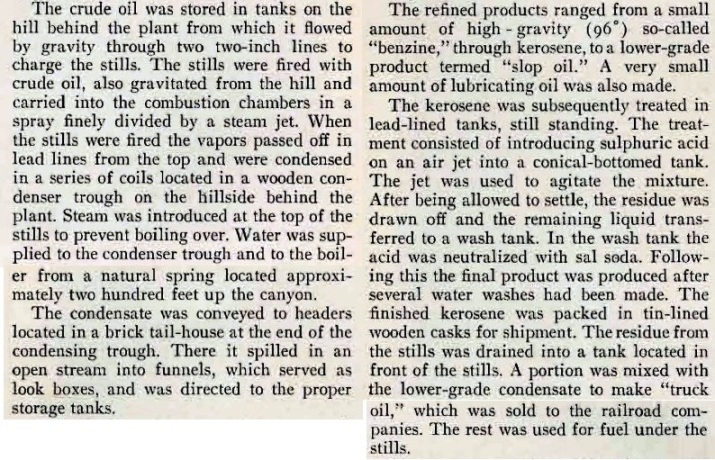

In the early years of the oil industry, a refinery was little more than a still where the crude oil was boiled and the different products were condensed out at various temperatures. The skills required were not all that different from making moonshine, which is why whiskey makers in the nineteenth century often went into the oil refining business. Refinery techniques varied from refiner to refiner so there is no one method that was used at the Pioneer Refinery because there were many different refiners over the relatively few years the refinery was in operation.

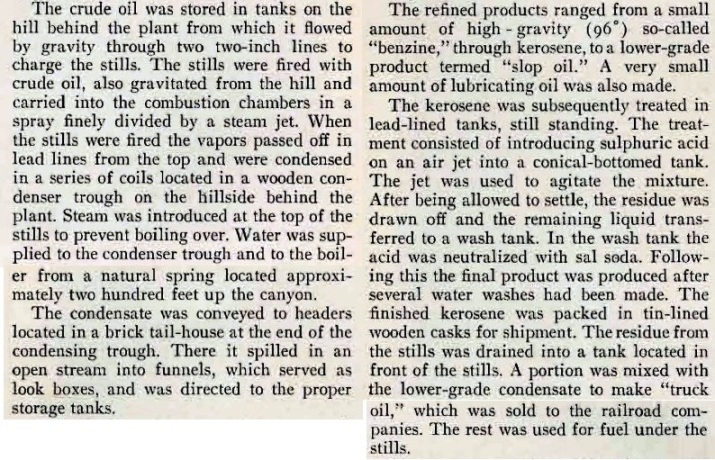

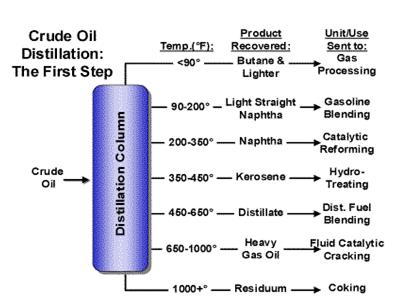

Crude oil consists of a complex of many different hydrocarbon compounds of various weights and densities. Each compound has a different boiling point. The fundamental principle in oil refining is called fractional distillation. This involves the heating of crude oil to an increasingly higher temperature. With each incremental increase in temperature, different compounds evaporate and these are subsequently cooled to give the various products. Other more complex treatments were often carried out after this basic process. However, the temperature is not just increased and increased, but carefully controlled to get the most distillates for the product desired.

It typically took from 24 to 36 hours to run off the contents of a 100-barrel still. The first group of products distilled were gasoline (or naphtha), benzene, and kerosene. The second group of products were the illuminating oils followed by the heavier lubricating oils.

At the Pioneer Refinery, the first step in the refining process consisted of getting the crude oil into large hollow containers – the stills. They were made of heavy boiler-plate iron and were capable of withstanding a high degree of heat. The refinery eventually had four stills with capacities of 15-barrels (630 gallons), 20-barrels (840 gallons), 100-barrels (4200 gallons), and 150-barrels (6300 gallons). The stills were enclosed in, and supported by, heavy brickwork and suspended over large furnaces. Tanks stored the crude and gravity allowed the crude to flow through pipes (the charging lines) into the stills when needed.

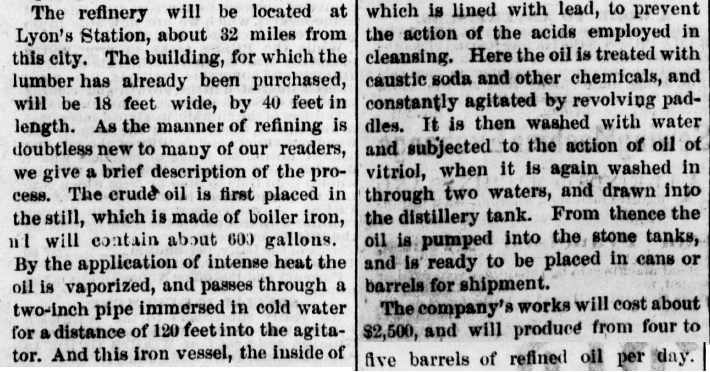

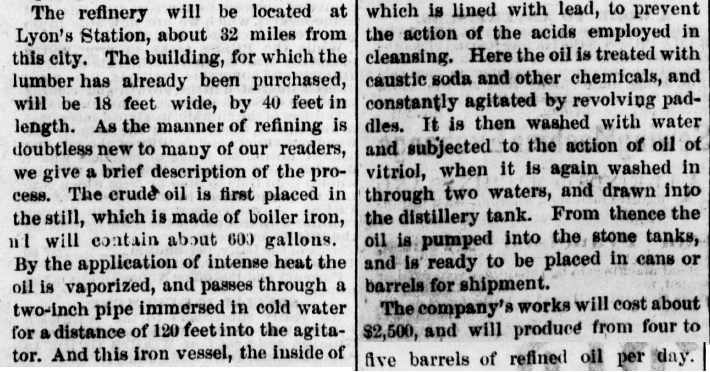

The Los Angeles Herald of December 13, 1873, provided a description of how the refining was going to be done at the Lyon's Station refinery.

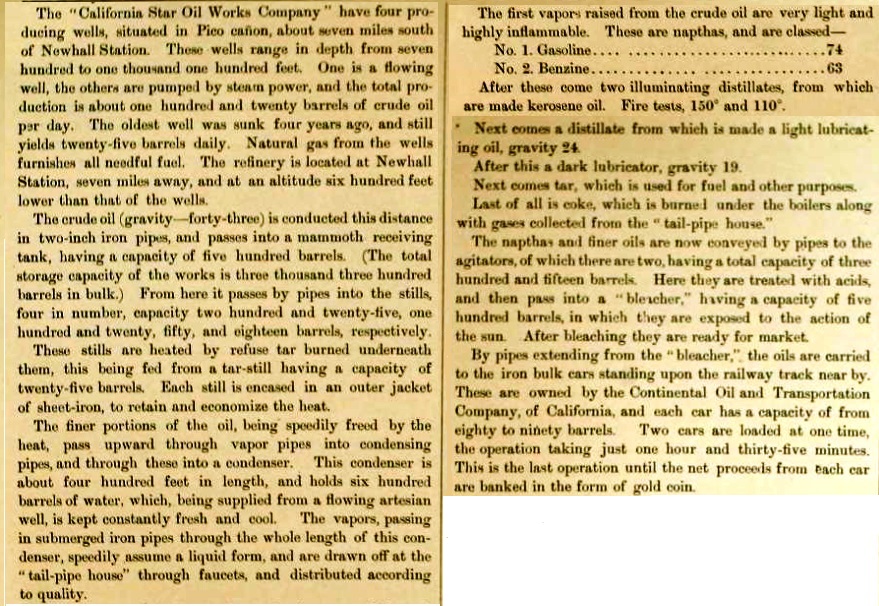

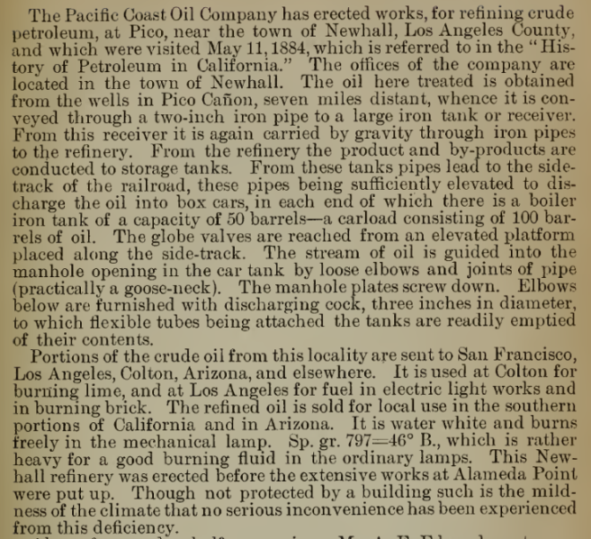

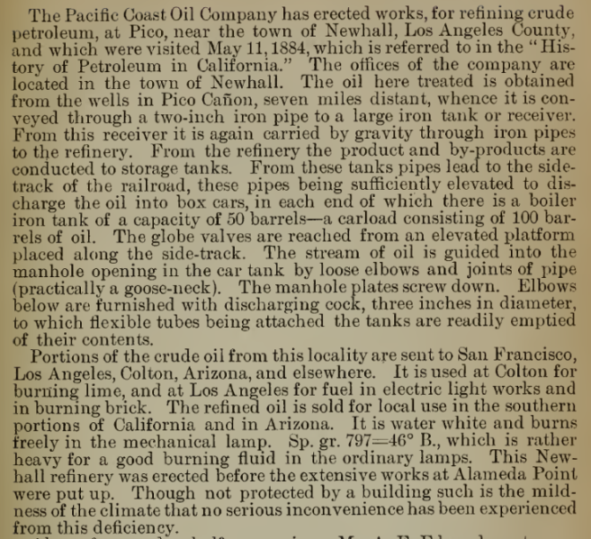

An 1880 description of how the refining was done at the Andrew's Station refinery from the History of Los Angeles County, California, by John Albert Wilson (Thompson & West, Oakland, Cal, 1880, p.69). Newhall Station was the railroad station in town north of Andrew's Station.

This description is from the Fourth Annual Report of the State Mineralogist for the Year Ending May 15, 1884, California State Mining Bureau, Sacramento, 1884, p. 303.

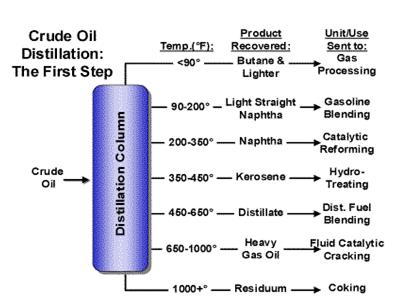

Another description of refinery operations was by Charles D. Kellogg for the September, 1930, issue of the Standard Oil Bulletin (p.4-5).

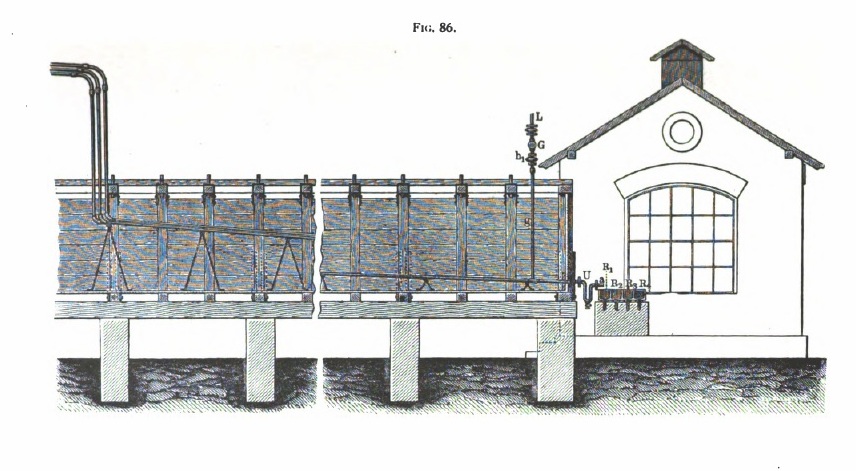

The Pioneer refinery's condenser consisted of 1,400-feet of two-inch and three-inch iron pipe enclosed in a 5-feet x 5-feet x 125-feet wooden trough filled with cool water. The pipes are still on site, but the wooden trough is long gone.

In the tail-house (or receiving house or running room), the distillates were checked, tested if necessary, and re-directed to the correct tank based on specific gravity and other physical tests. The man in charge here was called a "stillsman". For some reason, the tail-house was not restored in 1930.

Fraction distillation - the distillation column - different products condense at different temperature ranges (from the U.S. Enery Information Administration - EIA - website)

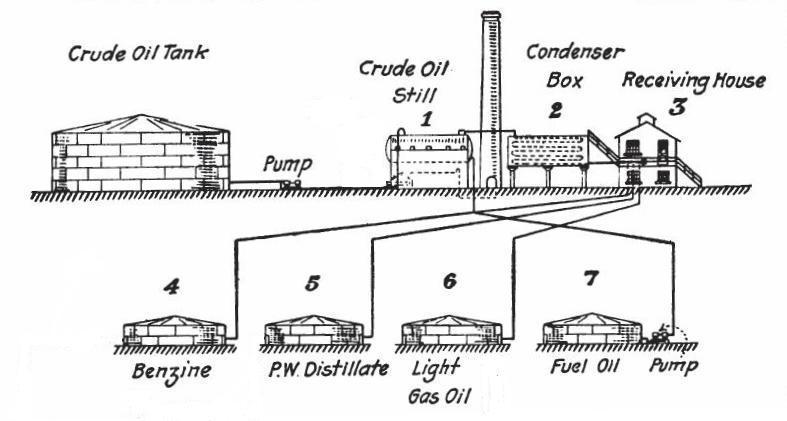

Refinery diagram (Modified from Hager, 1921)

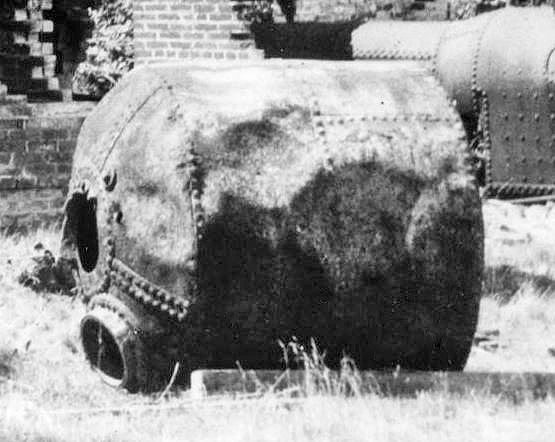

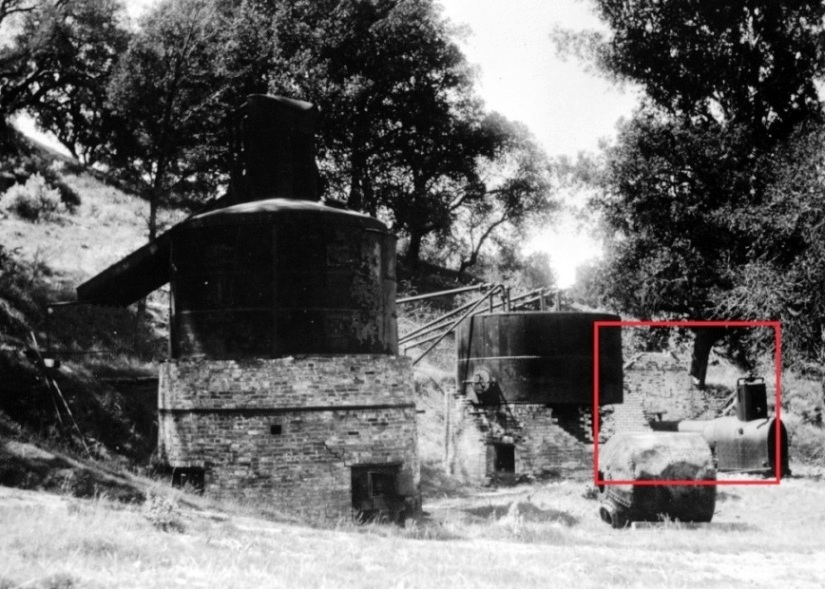

The oldest still at the refinery was this gooseneck type with a capacity of 15-barrels (630 gallons). It was originally at the Lyons Station refinery. Here it is lying on the ground (without the gooseneck) before the 1930 restoration of the refinery.

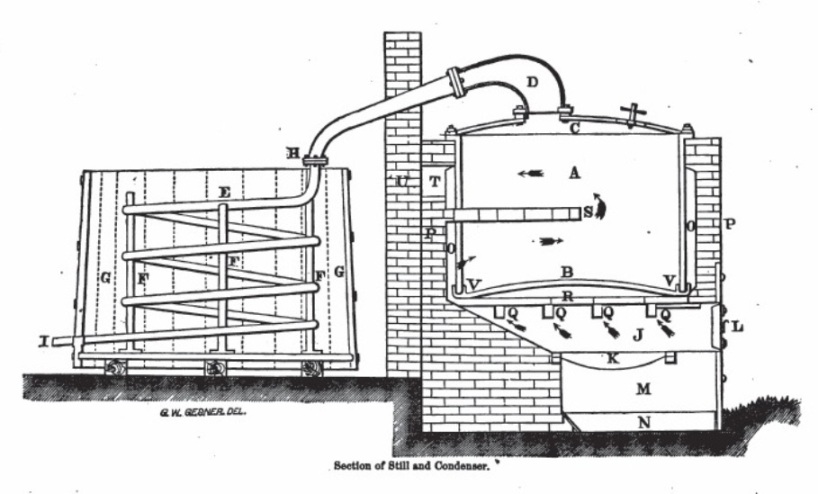

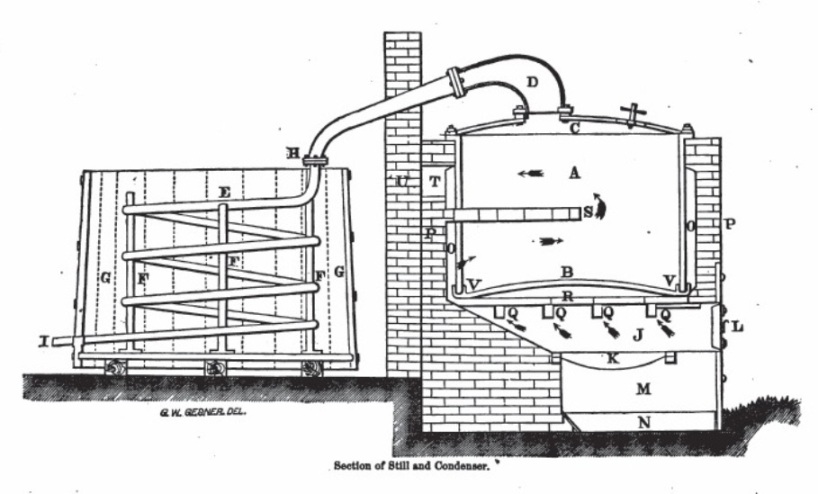

Diagram of a gooseneck still connected to a condenser (From Gesner, 1865)

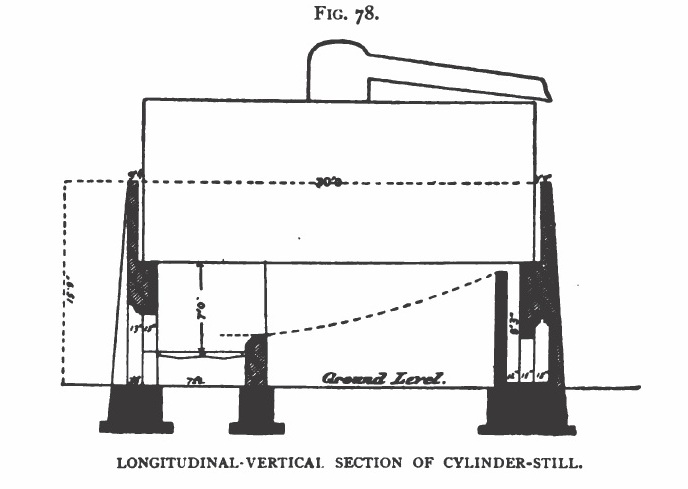

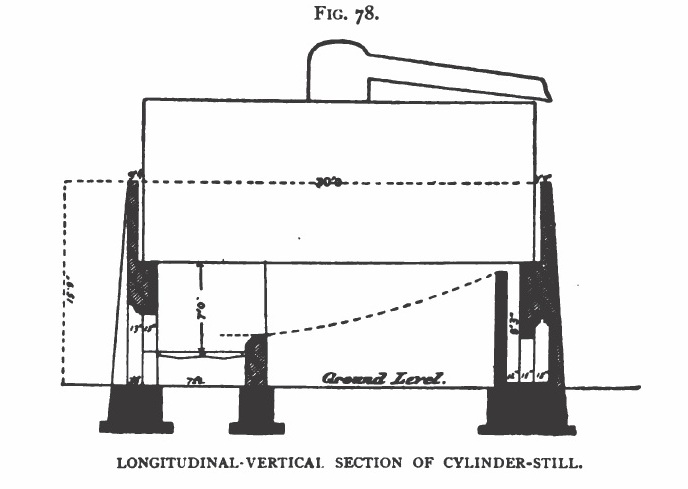

Diagram of a cylinder still (from Brannt, 1895). Still #2 was a cylinder still. This still style was popular for its cheapness of construction, simplicity, easiness to repair, and the largest amount of work accomplished with a given quantity of fuel.

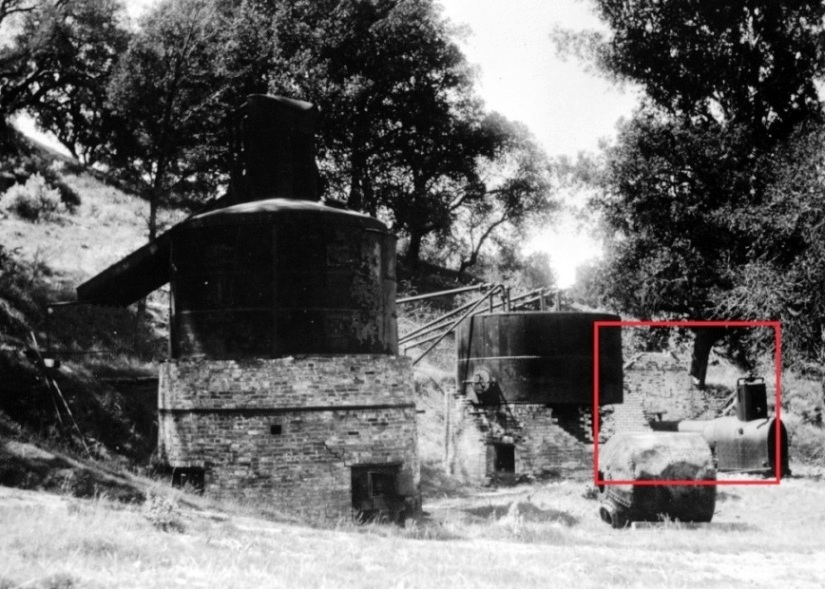

This photo gives a good view of all the stills. From left to right, Stills 4 and 3 were cheese-box style, still 2 was a cylinder style, and still 1 was a gooseneck style. Stills 1 and 2 were probably joined in one brick base because it was more economical to do so. The heat under each still would contribute to the heating of the other still. Circa 1940's (Photo by Arthur B. Perkins)

Copyright Note: This image is NOT in the public domain and was used by permission of the SCVHistory website.

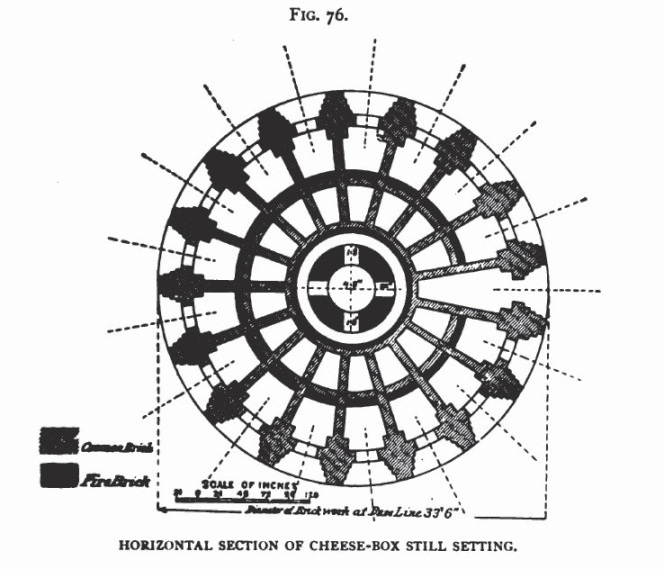

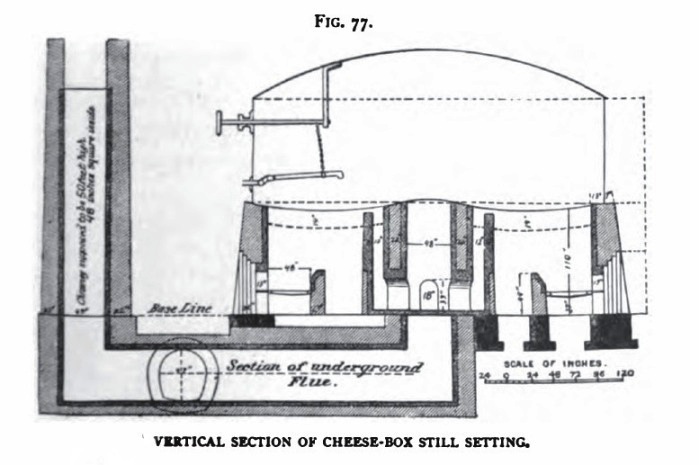

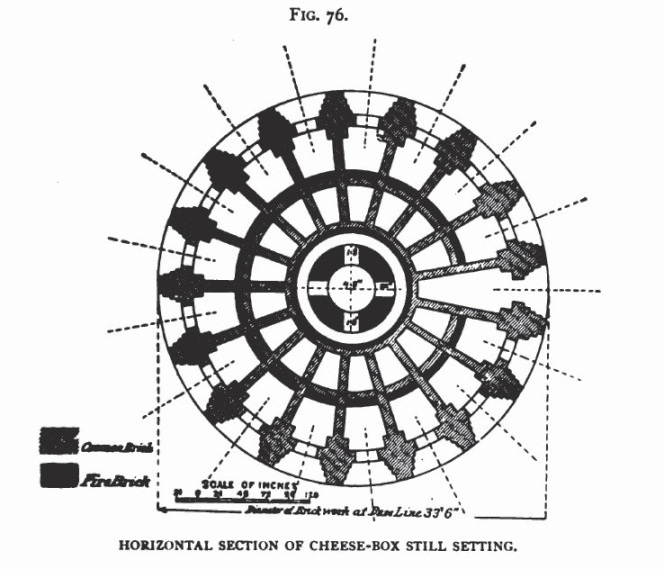

Horizontal section of a cheese-box still (from Brannt, 1895). Stills #3 and #4 were cheese-box stills. This still style was popular for the production of a larger yield of illuminating oil and of lighter gravity and superior color of distillates.

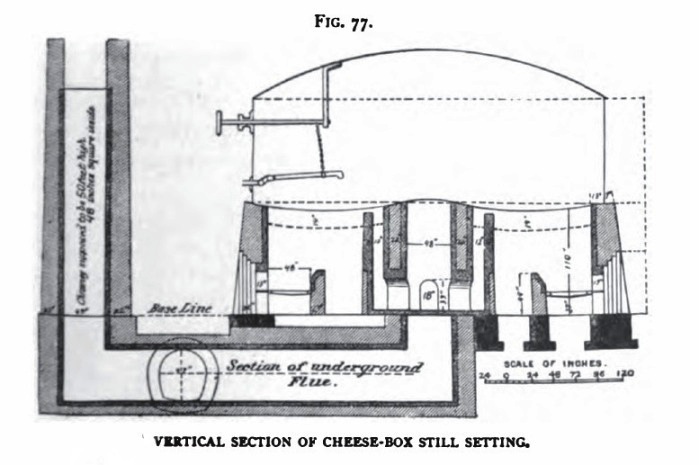

Vertical section of a cylinder still (from Brannt, 1895)

The condenser pipes were enclosed in a large wooden trough (5x5x125-feet). The trough obviously no longer exists. (8/14/2010)

"Piping from the top of still No. 4 is connected to the water filled condenser box." Figure 7 from the document "Pioneer Oil Refinery, 1876, The First Successful Refinery in California, National Historic Mechanical Engineering Landmark, 1975",

The American Society of Mechanical Engineers, September 27, 1975.

Closer view of the end of the pipes behind still #4 (8/14/2010)

The end of the pipes. Next stop the tail-house (8/14/2010)

Closer view (8/14/2010)

You can sort of make out the vertical set-up of the pipes (8/14/2010)

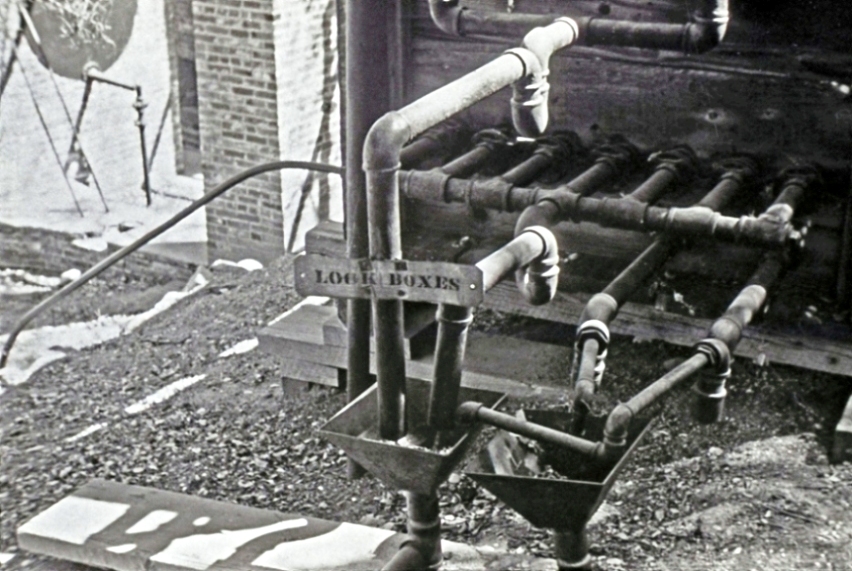

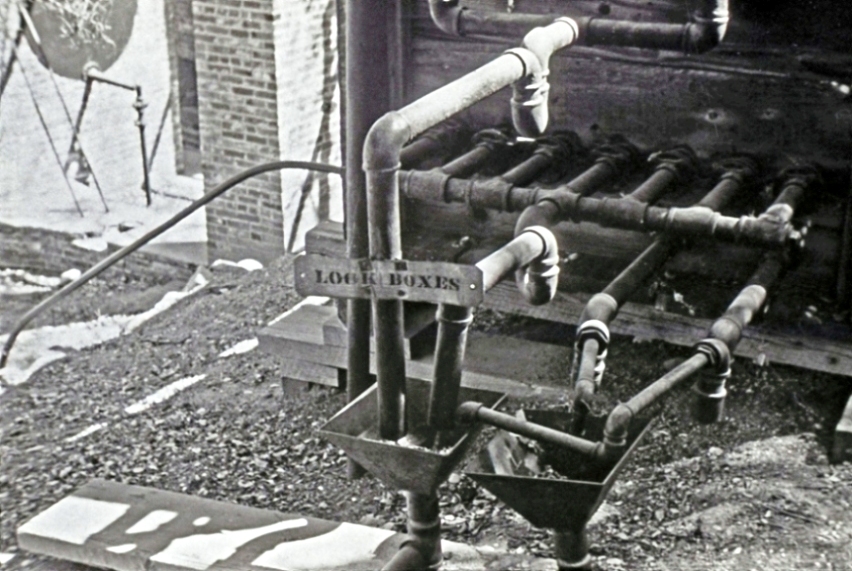

View (probably from the 1940's) of the pipes where they come together to be separated into different products. This was probably in the tail-house, which was not restored during the 1930 restoration. It may have not been restored because the building would have hidden the lock boxes and they wanted to show everything out in the open. (Photo by Arthur B. Perkins)

Copyright Note: This image is NOT in the public domain and was used by permission of the SCVHistory website.

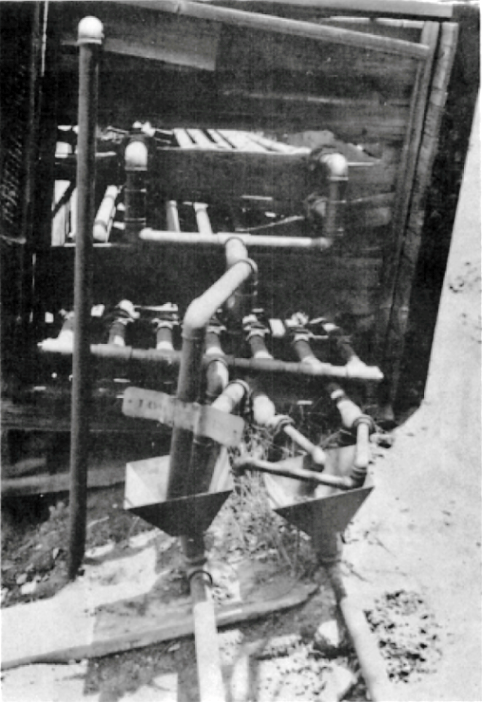

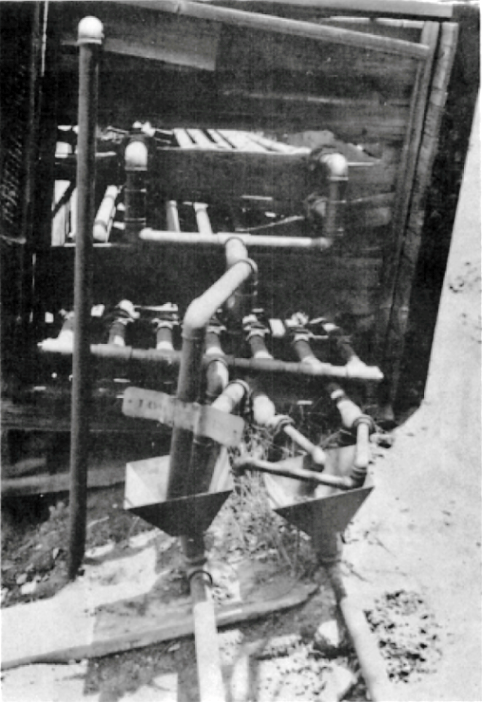

"An end view of the condenser box on the hillside above the stills, showing the various layers of piping and funnels to collect the product." Figure 9 from the document "Pioneer Oil Refinery, 1876, The First Successful Refinery in California, National Historic Mechanical Engineering Landmark, 1975", The American Society of Mechanical Engineers, September 27, 1975.

This is the far right part of the famous 1880 photo of the refinery in action. There looks to be a small building there (in the red rectangle) with the roof sloping down to the front and a small window (or possibly the top of a door) just behind the gooseneck still. This would be where the tailhouse was.

Poor quality 1920 photo showing the refinery. There is obviously a roofless building with a door in the red rectangle. However, the roof slopes in a different direction than the 1880 photo. Is this the tailhouse?

Photo from around 1930 just before the refinery restoration. Here, the rear of the 1920 building is all that remains, but the slope of the roof is the same as 1920.

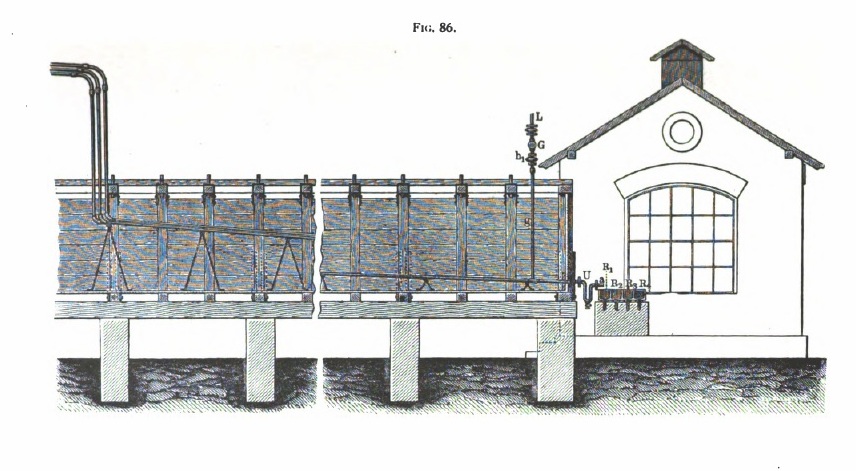

Here is a diagram of a condenser and tail-house similar to the one at the Pioneer refinery (from Brannt, 1895)

The acid tank (7/17/2010)

The conical bottom of the acid tank (7/19/2010)

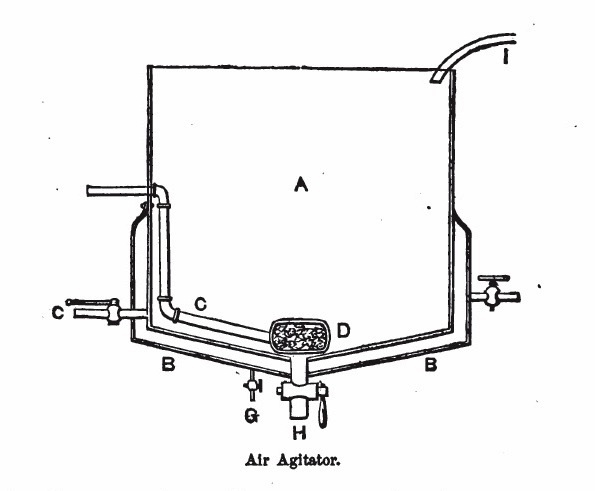

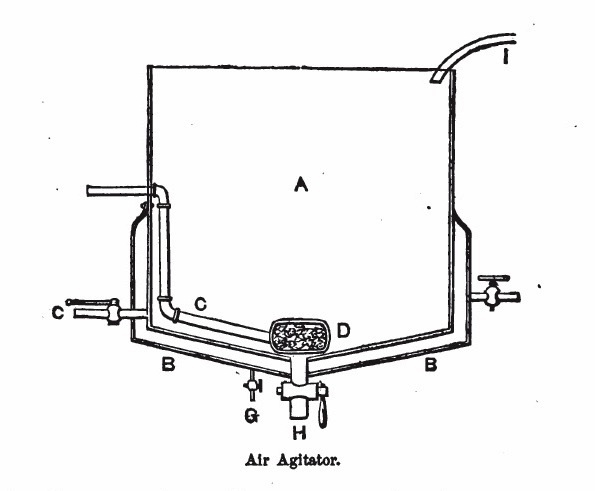

Agitator tank (from Gesner, 1865). The parts are "A" - Boiler iron surrounded by a steam-jacket "B" at the bottom and part of the sides. A two-inch pipe, "C", connected to a fan or air-pump on one end and a perforated iron container, "D", on the other end. A steam-pipe and valve provide steam for the jacket. The drip-cock, "G", carries off the condensed steam. The cock, "C", is the outlet to the settling tank for the oil after agitation. The pipe, "I", is the inlet for oil from the pump. The cock, "H", is for drawing off the acid residue.

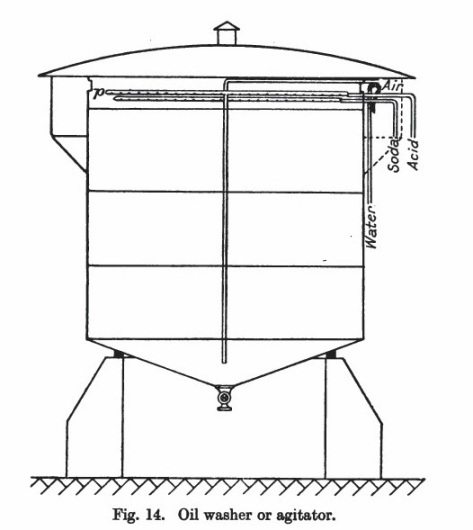

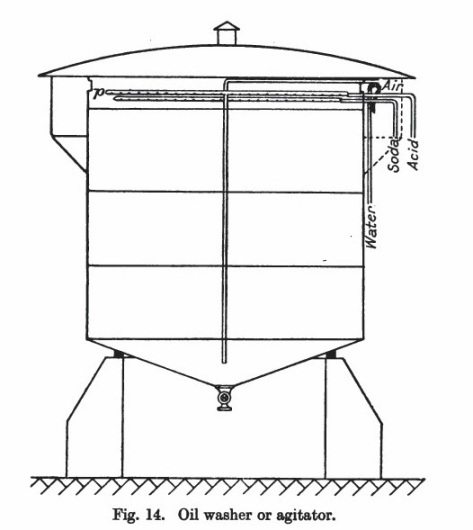

Wash tank or agitator tank (from Guttentag, 1918)

The wash tank (8/7/2010)

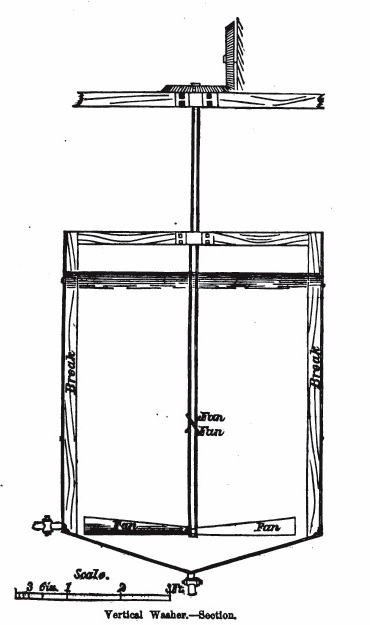

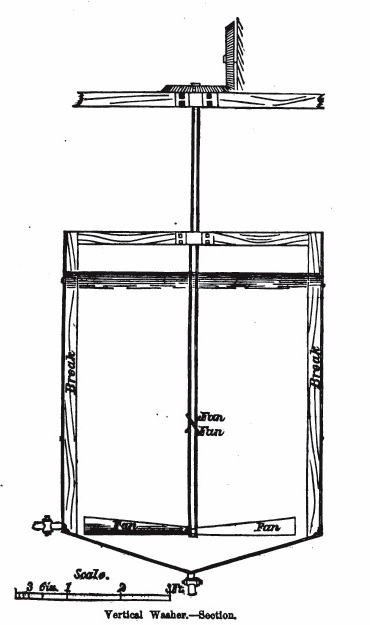

Vertical wash tank (from Gesner, 1865).

The kerosene and benzine storage tanks (6/20/2010)

Tank used to collect the residue from the stills after the refining runs (5/25/2013)