St. Bernard Oil Company Well No. 1

This unique well deserves its own page not only because it is the most remote well in Towsley Canyon, but it is also one of the most complete wells in the Newhall Oil District, only matched by the Occidental Petroleum well in East Canyon. This site contains the uncapped leaking wellhead (see above), a boiler, a steam engine, a sand reel, a band wheel shaft, and a large amount drilling cable.

There is very little information about this well since it was drilled before the existance of the Division of Oil and Gas (DOG).

The most complete description is from Prutzman, 1913, Petroleum in Southern California, California State Mining Bureau, Bulletin 63:

"St. Bernard Oil Company. The well of this company is in the west fork of the canon, and nearly a mile and a half, following the windings of the gulch, above the other wells. This well was drilled in 1903, to a depth of 2100 feet, and is said to have encountered oil at several levels, but with no production. In 1911 this well was reported to be again drilling, but was not visited."

Kew (from 1924) also adds that the well "is practically on the axis of the large syncline [the Oat Mountain syncline] south of the Pico anticline."

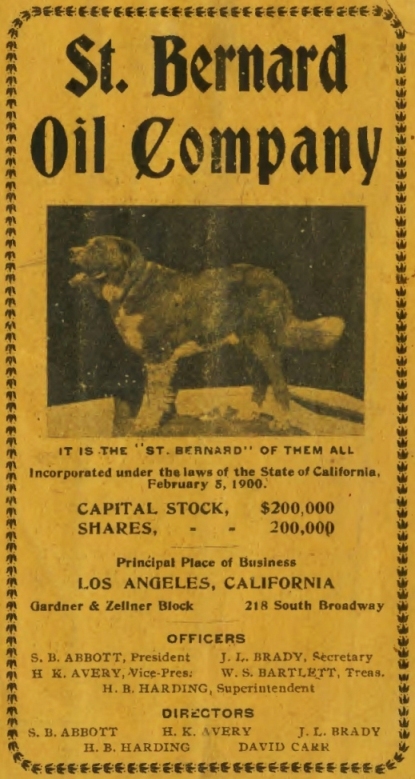

Articles of incorporation of the St. Bernard Oil Company were signed and certified on January 27, 1900. The amount of capital stock was $200,000 for 200,000 shares with a par value of $1.00. The amount of actual subscribed shares was $120,000. The first officers were S.B. Abbott (President), H.K. Avery (Vice-president), J.L. Brady (Secretary), H.B. Harding (Superintendent), F La Strong (Geologist), and W.S. Bartlett (Treasurer).

Unfortunately, the well was never successful. On November 30, 1909, and on November 30, 1910, their right to do business in California was forfeited for failure to pay their corporation license tax. (From the State of California: Certified Copy of Compiled Statement of Domestic Corporations Whose Charters have been Forfeited and Foreign Corporations Whose Right to do Business in this State has been Forfeited at 4 O'Clock P.M. November 30, 1909 and 1910).

On this hike, I was joined by Robert Miller. He had previously visited the well site with his friend in 2003 and 2007. Although I knew that I would eventually find the site, he could lead me directly there, saving me much time and effort. Thanks, Robert. All photos were taken on 1/9/2010, the day of our hike.

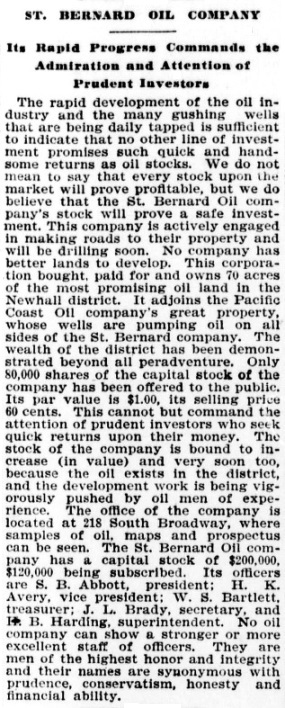

From a St. Bernard Oil Company promotional pamphlet, n.d.

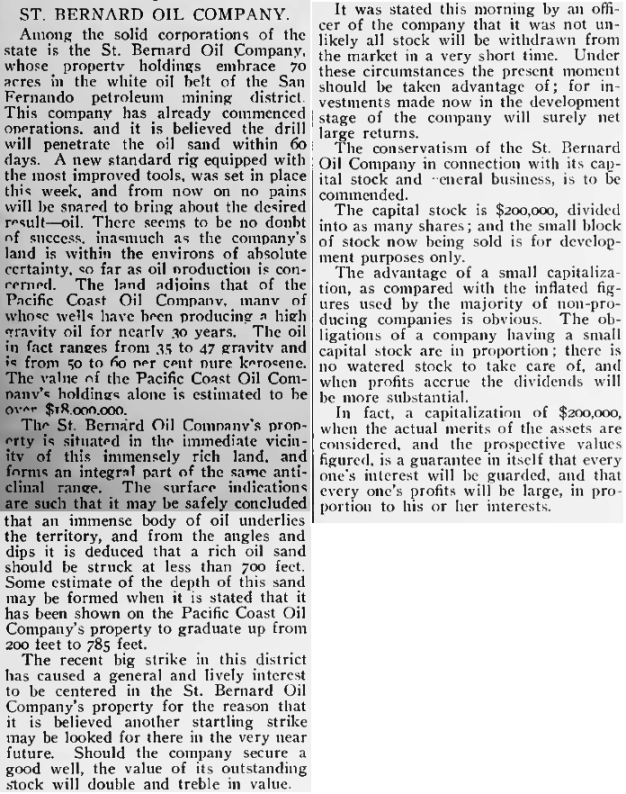

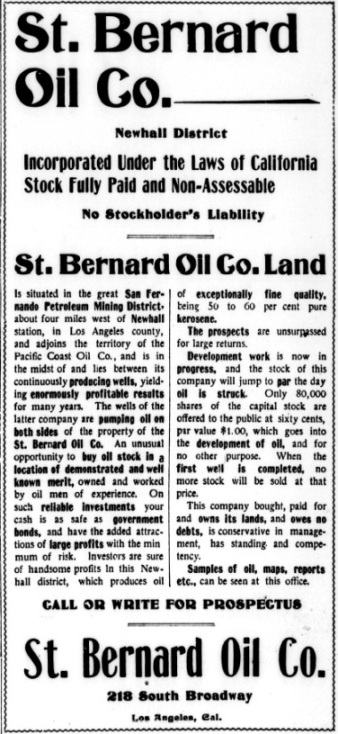

From the Los Angeles Herald of February 2, 1900

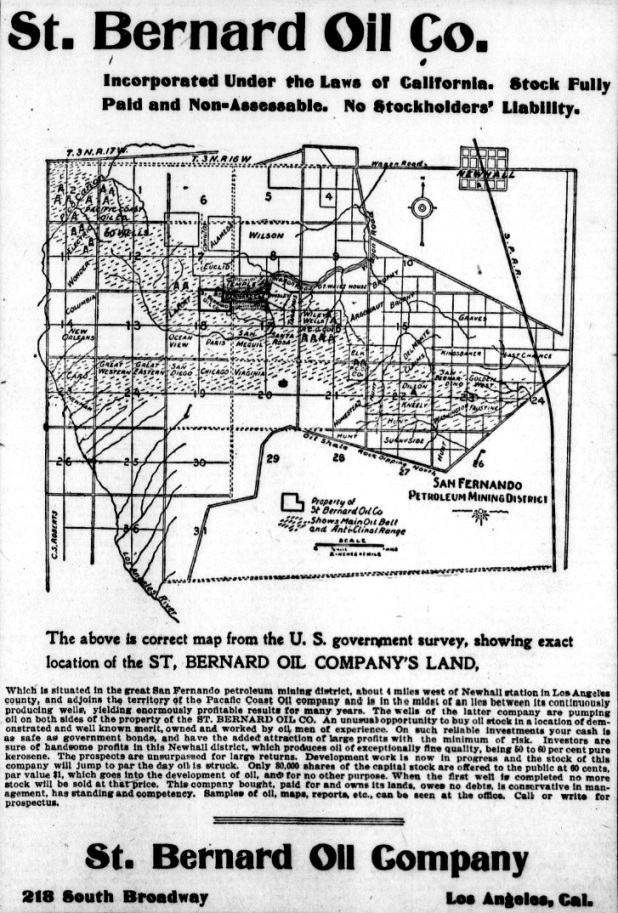

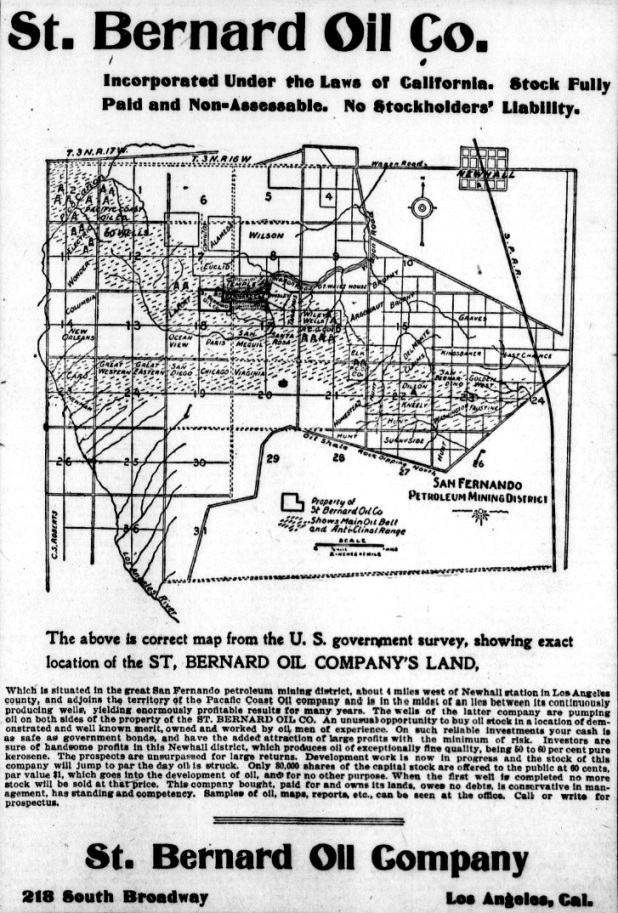

From the Los Angeles Herald of February 18, 1900

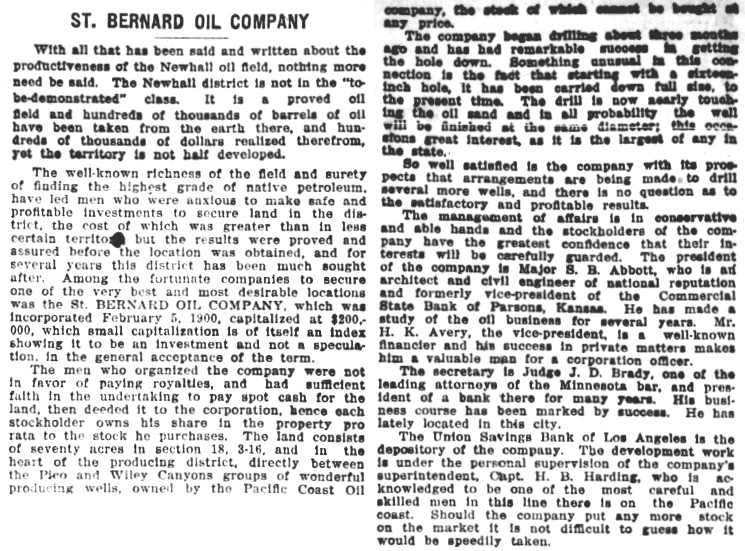

From the Los Angeles Herald of March 11, 1900

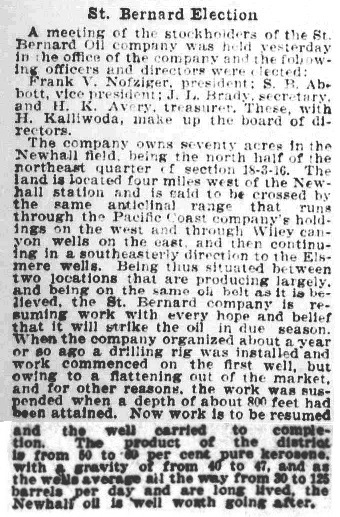

From the Los Angeles Herald of May 6, 1900

From the Los Angeles Saturday Post (newspaper) of September 1, 1900

From the Los Angeles Herald of December 2, 1900

From the Los Angeles Herald of June 15, 1902. No commercial oil deposits were ever found.

Looking down the west fork of Towsley Canyon. This is going to be a difficult hike. The old road to the well site is almost completely gone due to landslides and erosion. (All photos taken on 1/9/2010)

Easier section of the creek bed to hike through

There are a few waterfalls that need to be climbed. Robert is at this one.

There are some deposits of oil stained shale (pointed out by Robert) that probably encouraged the early oil seekers

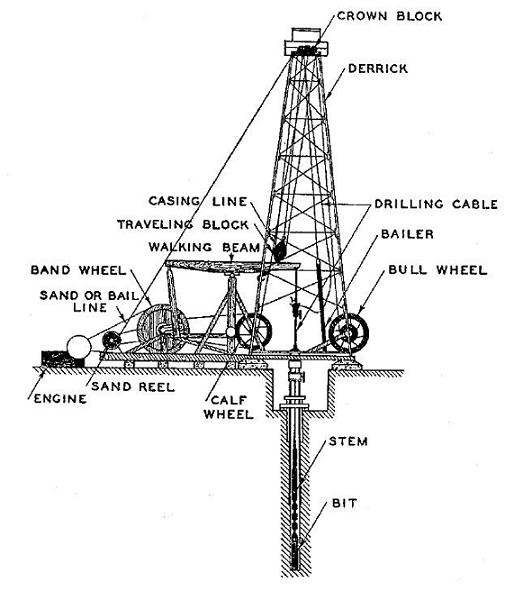

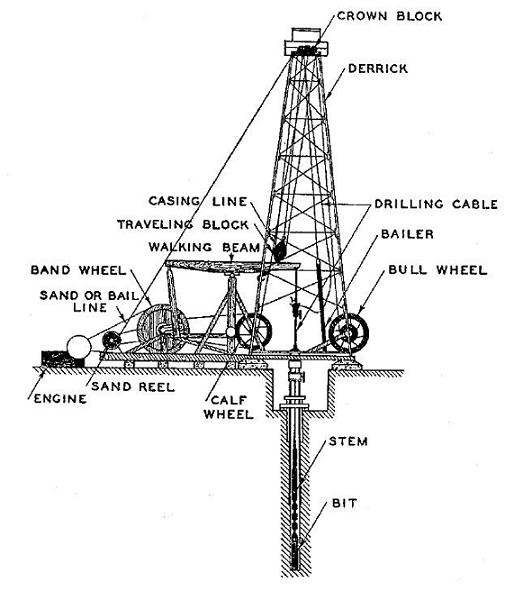

Before we get to the well site, here is a simplified cable-tool rig diagram. See the Elsmere Canyon cable-tool rig page on the oil page for more details.

The first sign that a well is nearby is this smokestack from a boiler

Past the smokestack in deep brush is this horizontal tubular boiler. This is actually the original location. The two settings for the boiler are almost totally buried below it. There is one setting in the front and one in the back that support the boiler. The boiler is about 13 feet in length and 42 inches in diameter. It weighs about 5300 pounds and probably cost about $425 (estimates from the 1916 Oil Well Supply Co. catalog).

Boiler dome. There was a pipe extension from here that attached to the steam engine. The steam flowed from the dome to the engine.

On on end of the boiler are 32, 3 inch diameter tubes. The boiler maker was Brownell & Co, Dayton O. It probably generated about 40 horsepower.

From various sources on the internet comes this information about Brownell & Co:

The firm of E.H. Brownell was begun in 1865 by Elijah H. Brownell in a small shop in Dayton, Ohio. It incorporated in January of 1888 and re-incorporated in 1903 with capital stock of $950,000. By 1909, its plant covered 13 acres and was employing 300 people. Its annual capacity was 2500 boilers and 500 engines. It was shipping to all parts of the United States, Canada, Mexico, and Alaska.

Some sort of clamp on the other end.

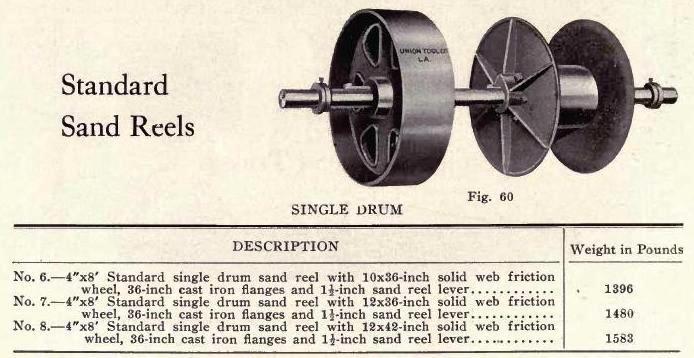

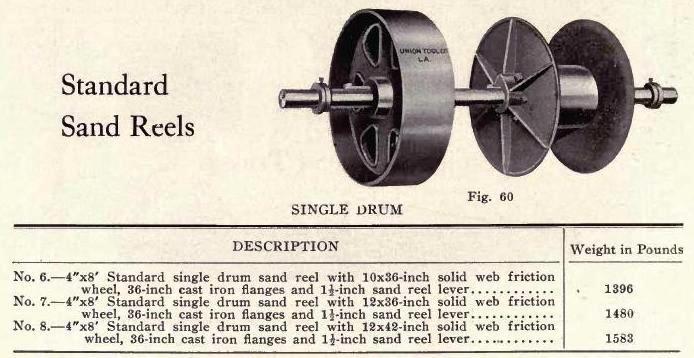

Leaning on the boiler is a single drum sand reel. Sand reels held the sand line cable for the bailer. The bailer was used to clean out crushed rock and earth from the hole.

Another view of sand reel with the drum on the right (for the cable) and the pulley on the left. It probably weights about 1400 pounds and cost about $200 (in 1916).

The sand reel here in Towsley Canyon and the the one in East Canyon are the same style. Here is a sand reel from the 1914 Fairbanks Morse Oil Well Supply Catalog.

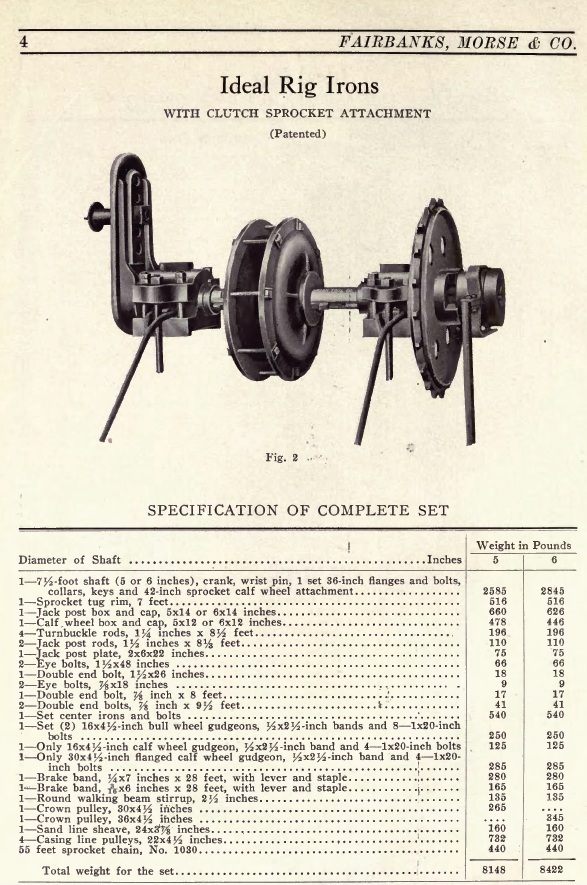

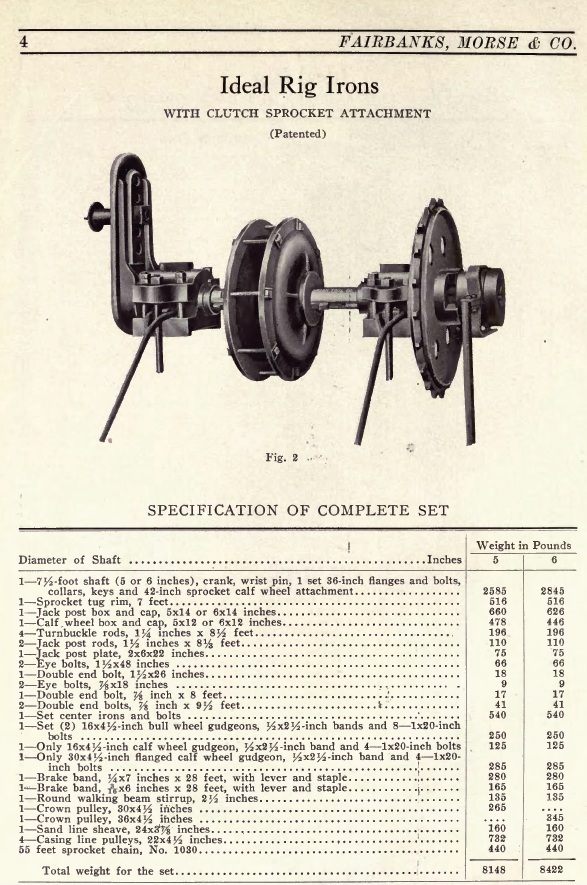

This is the shaft for the band wheel. It probably weighs about 2400 pounds. I couldn't come up with a cost because the catalog only prices each individual part.

A closer look shows that the maker was the Baker Iron Works of Los Angeles, Ca. Baker equipment has been found in other canyons in the Newhall Oil District.

The other end shows the crank partially buried and the 36 inch flanges, which would enclose the wooden band wheel. The crank is attached to the walking beam with the pitman. As the bandwheel moves in a circular motion, the pitman moves up and down. That movement is passed to the walking beam causing it to move up and down. The drill string is at the other end of the walking beam in the hole. The bit at the end of the drill string pulled up and down smashing over and over at the bottom of the hold crushing the rocks. At a certain point, the drilling string is removed from the hole and the bailer is lowered in to collect the crushed rocks and dump them away from the rig.

Band wheel shaft from the 1914 Fairbanks Morse Oil Well Supply Catalog. The actual shaft at the well site has a tug wheel attachment on the end and not the sprocket attachment shown in this catalog. The tug wheel would use a rope while the sprocket wheel would use a sprocket chain.

This is one end of the partially buried steam engine showing the flywheel, the crank, and the pulley

On the side near the other end of the engine is the engine maker. This says Farrar & Trefts, Buffalo N.Y., Bayne Wilson & Pratt Agents. It is hard to tell the weight of this engine because I don't have a catalog with this maker. It could weigh anywhere from 3000 - 6000 pounds depending on its horsepower.

Here is the actual well head. It is not capped and is leaking water. There is a green zone from the here down the slope toward the creek.

This cable must have been the drilling cable (also called wire rope). It is located near where the bull wheel would have been.

A lot of work was done at the well site to build this retaining wall between the well site and the slope to the creek. That piece of metal is actually a brake band.

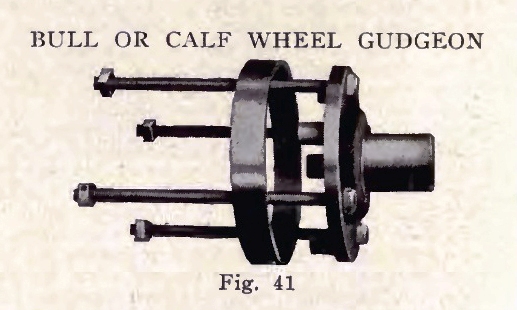

Gudgeon. One of these would be located at each end of a shaft probably for the bull wheel at this well

From the Fairbanks-Morse Oil Well Supply Catalog of 1914

Hook bolt

Valve on probably a water pipe

Old barrel. Note the "track" around the middle. Robert and his friend found an old barrel similar to this one at a mine site on Mt. Gleason. Their barrel had two tracks close to the middle. After researching steel drums, he believes that these are called "rolling hoops" and were intended to facilitate rolling and turning the early, brittle barrels and would also keep the barrel above the ground surface.

Looking down on the well site. There is almost no evidense of there ever being an oil well here from this high up. If you look real close, you can just see the top of the tug wheel from the band wheel shaft.

Robert standing at pool below small waterfall on the trip back from the well site

Another view of the pool. The patterns are certainly gone after the rains of 1/17 - 1/22/2010.