Gasoline Plant

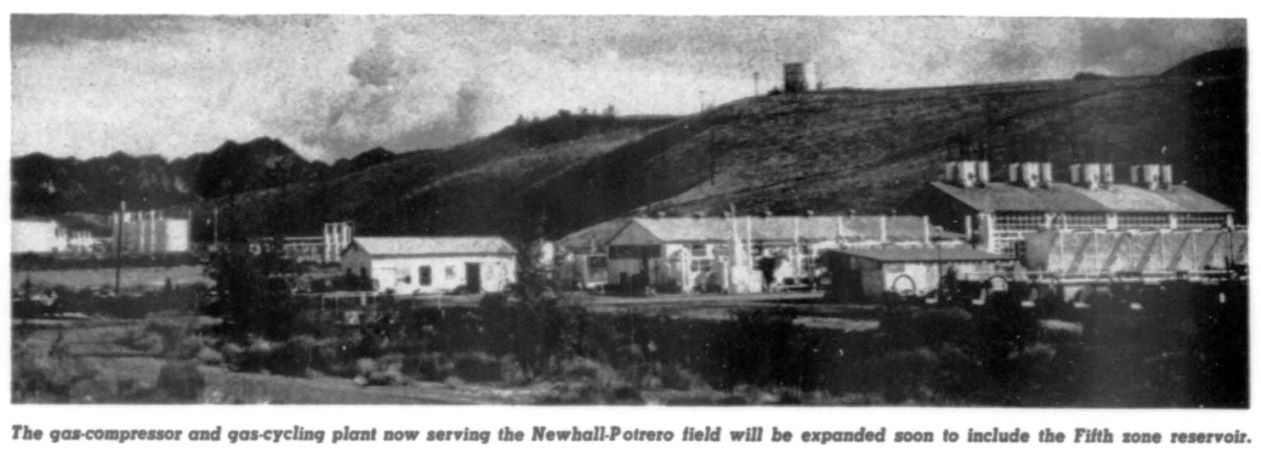

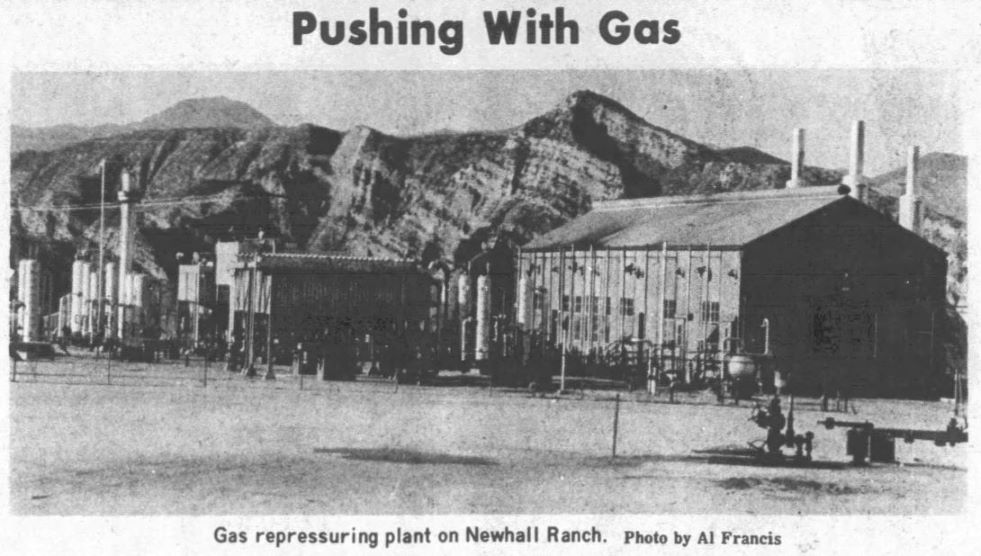

By 1944, Barnsdall had drilled 44 wells in the field, with only one (RSF 26) not a producer. However, it was noticed that the underground pressures that forced the oil into the wells were decreasing, causing oil production to drop. A study was done to determine what to do about it. The study would show that the best solution would be to return all available natural gas coming from the wells back into the oil reservoir. Production would be increased by about 41 percent. Experiments showed that gas could be returned from the surface into the reservoir using about 2,000 psi. A plant was constructed and a full-scale gas return program was started in mid-October of 1945. Some of the oil wells were converted to gas injection wells to do the job. The beginning average gas injection rate was 12,900 millions of cubic feet per day into the lower gas zones. By January of 1946, the total gas injection rate was 1,745,000 M c.f. (millions of cubic feet). By 1954, injection was also being done in the deeper zones.

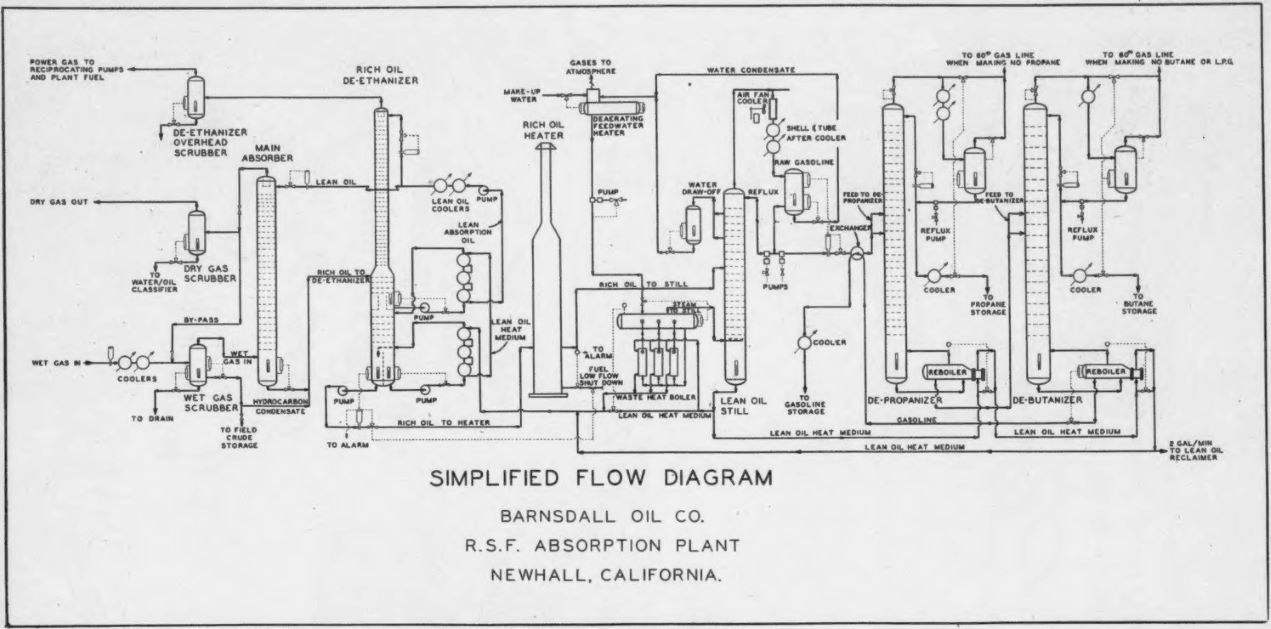

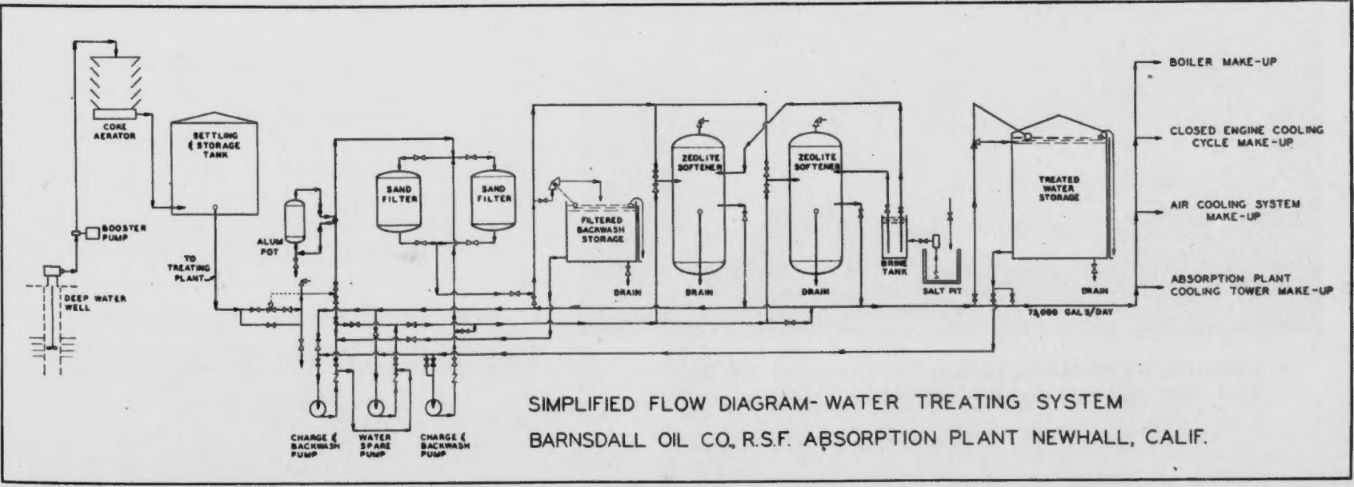

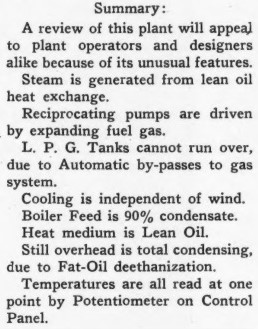

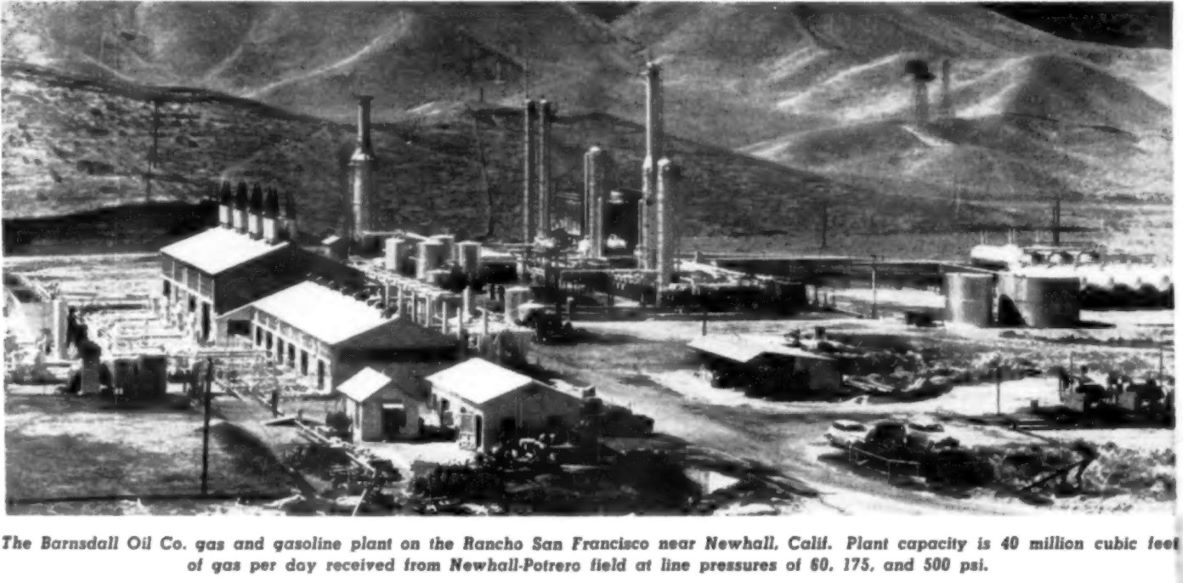

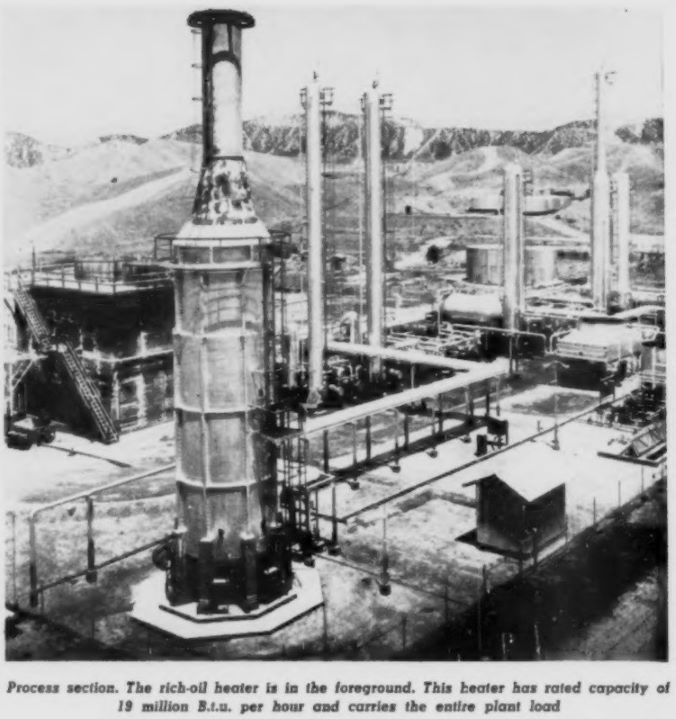

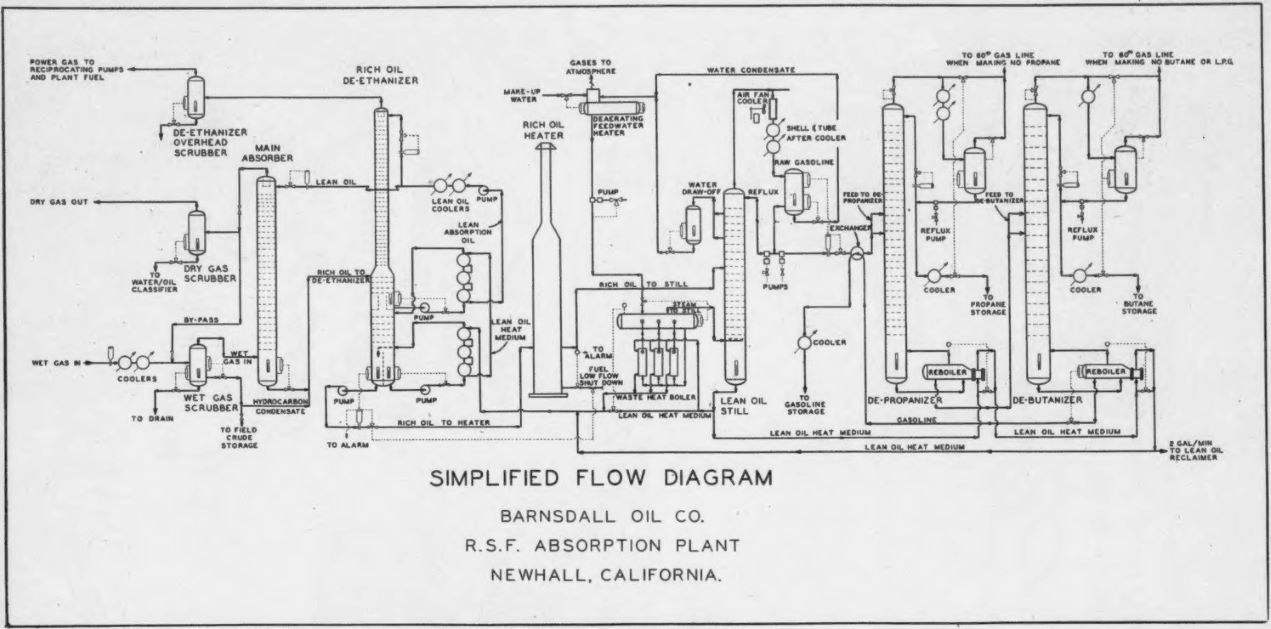

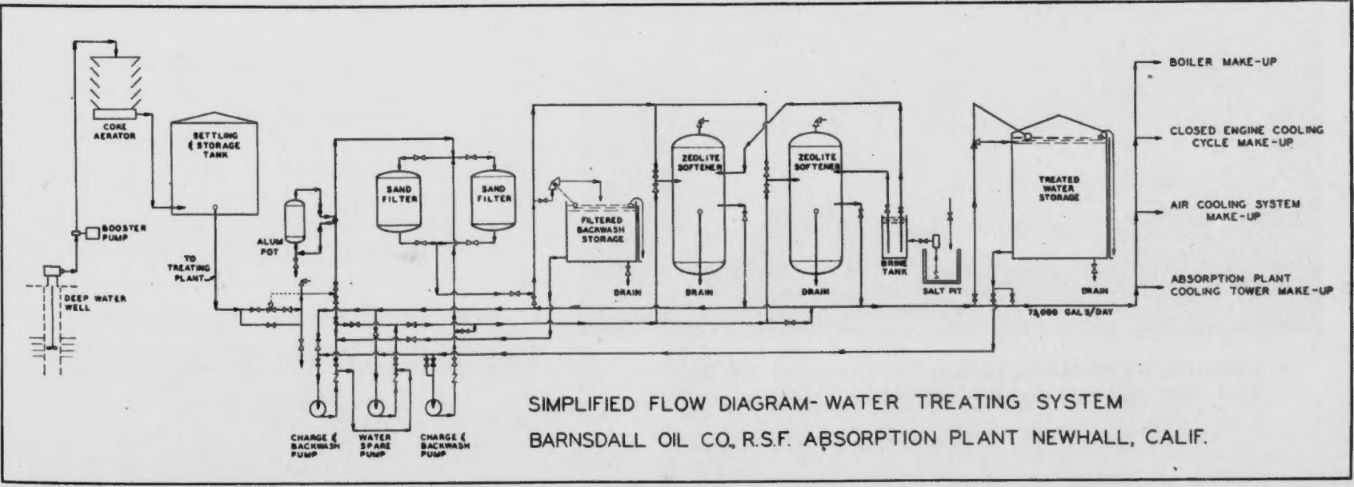

Features of the plant from the Oil & Gas Journal, June 9, 1949.

After 3 1/2 years of gas injection, it was estimated that about 1 million extra barrels of oil were produced.

On December 21, 1973, the Newhall Signal reported that 20 billion cubic feet of gas was pumped from the ground, but most of it was repressurized and returned to the oil pools to create pressure. However, the propane and butane was removed from the oil and sold to the gas company.

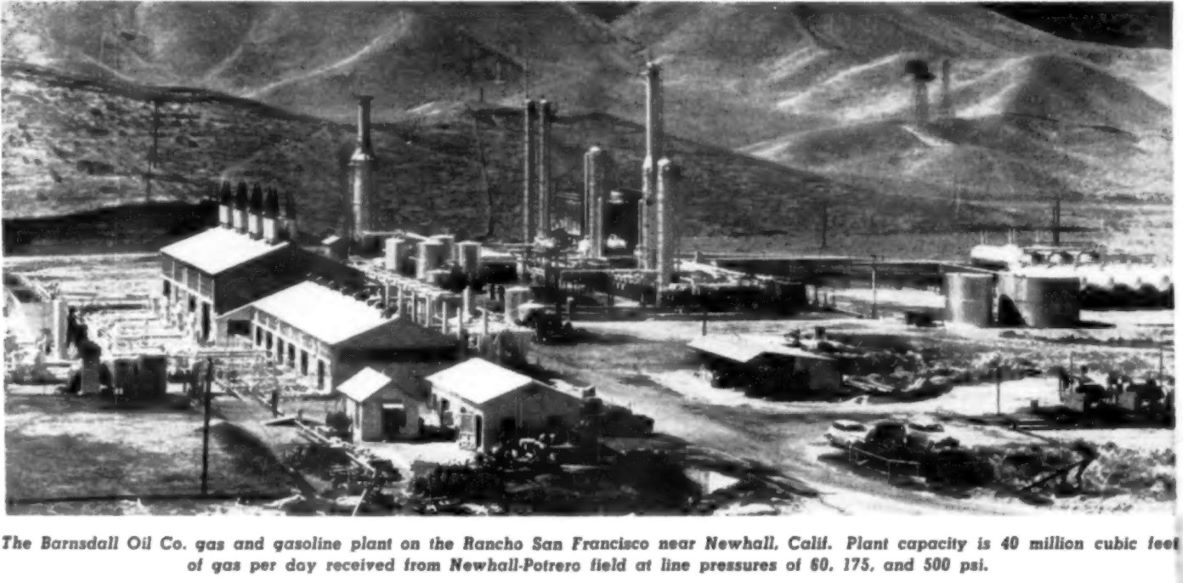

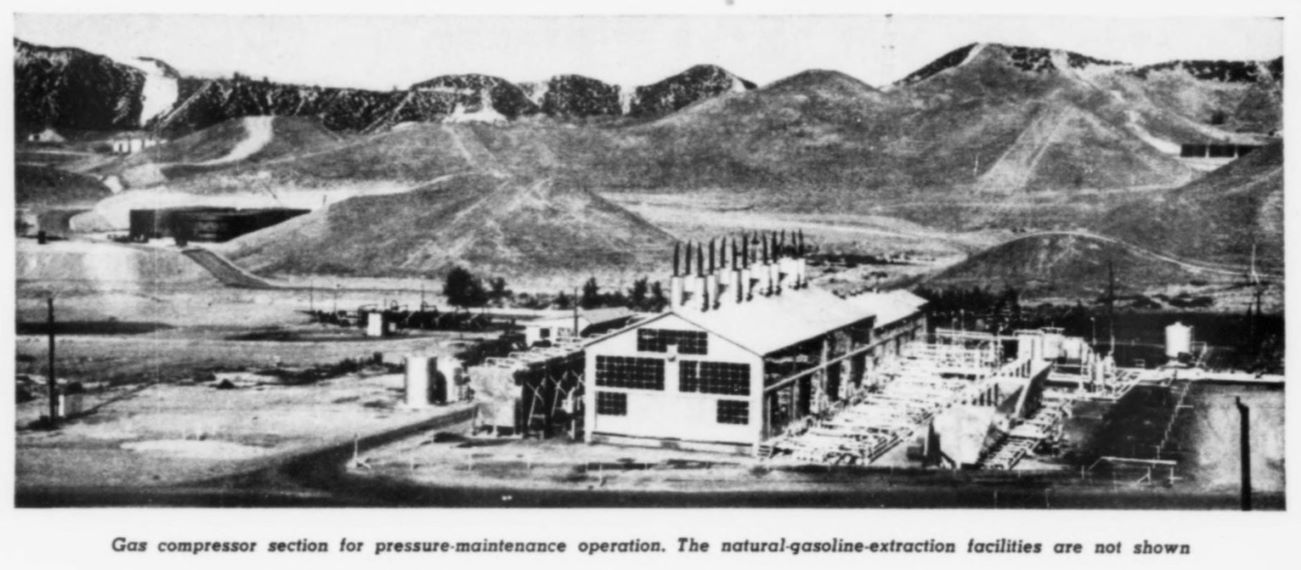

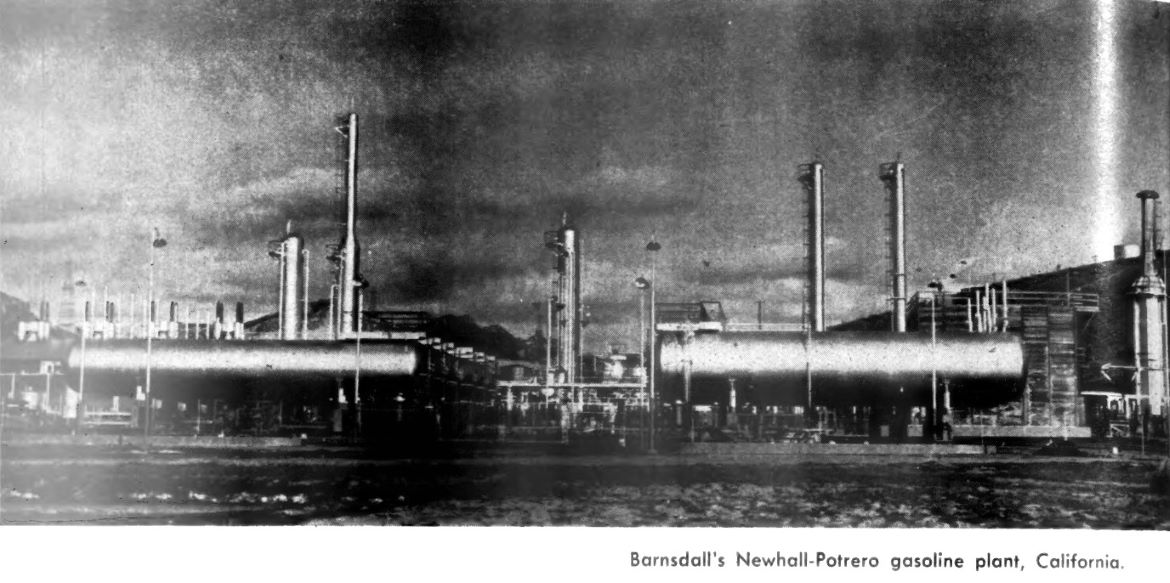

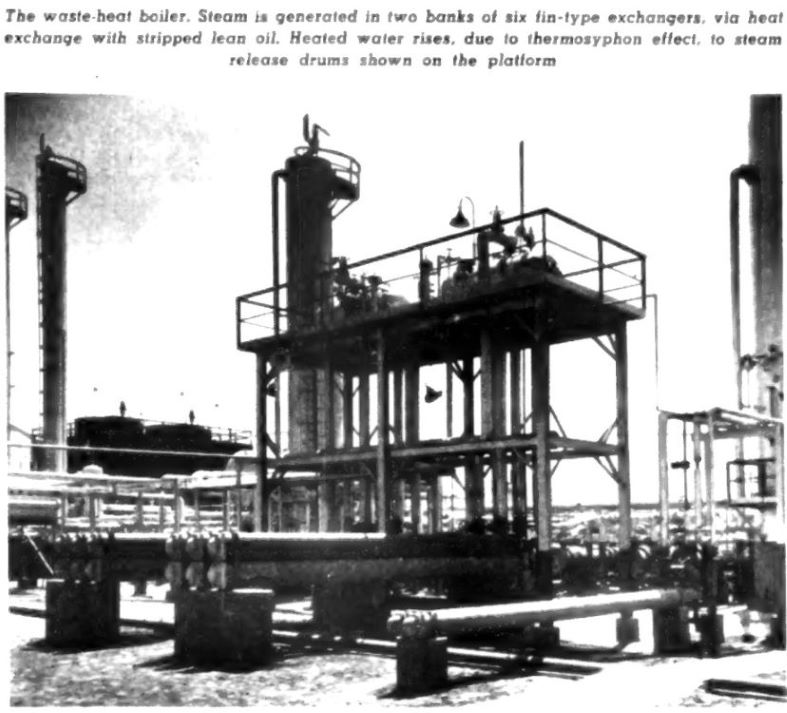

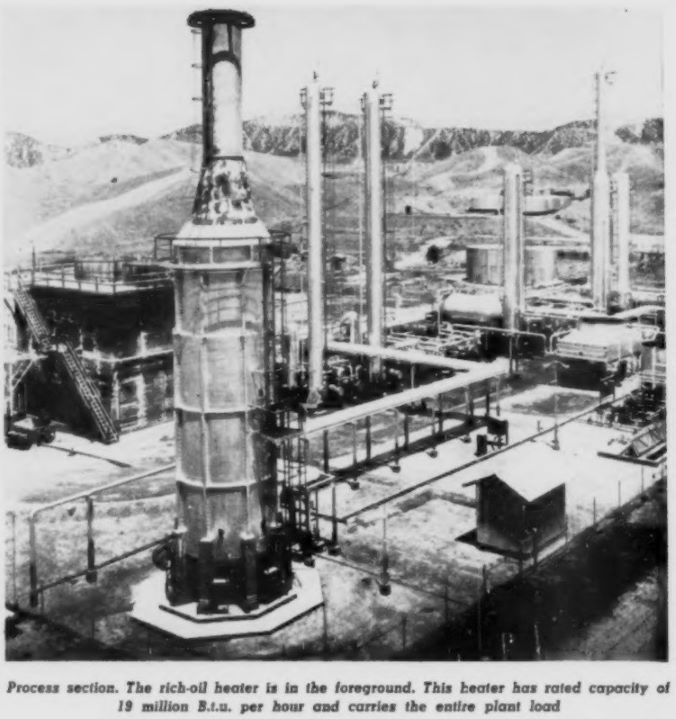

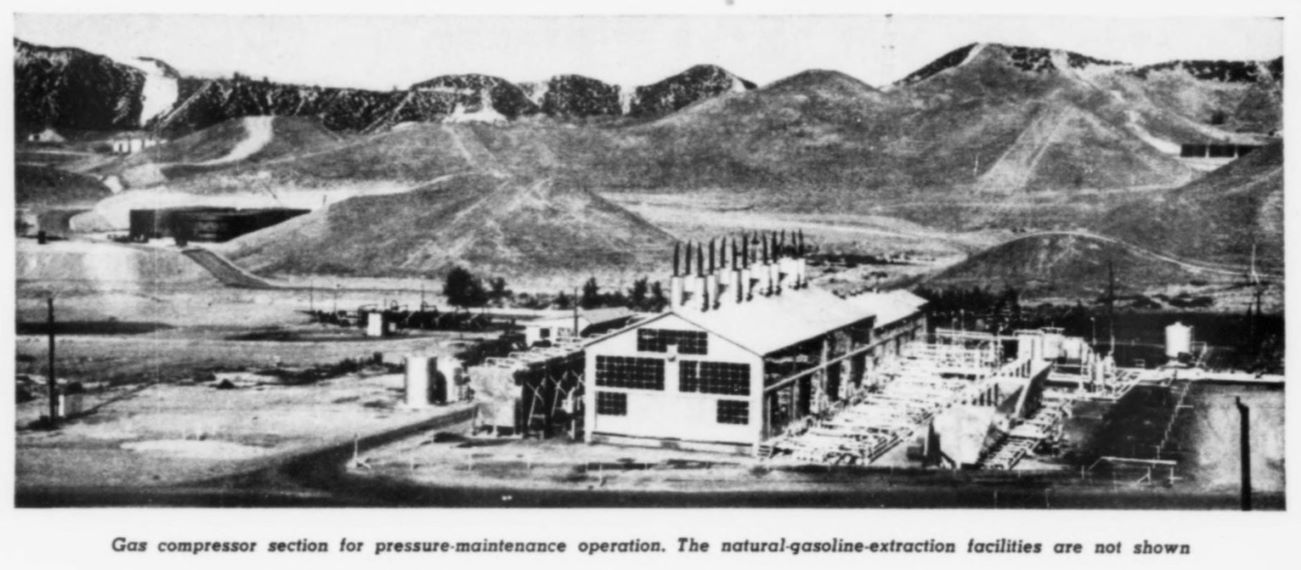

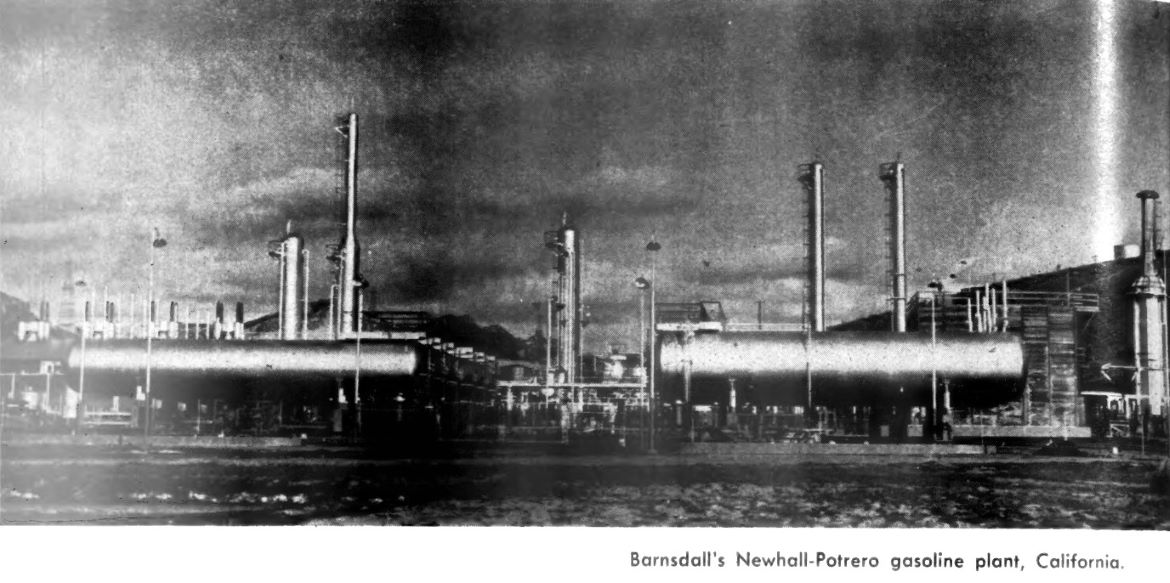

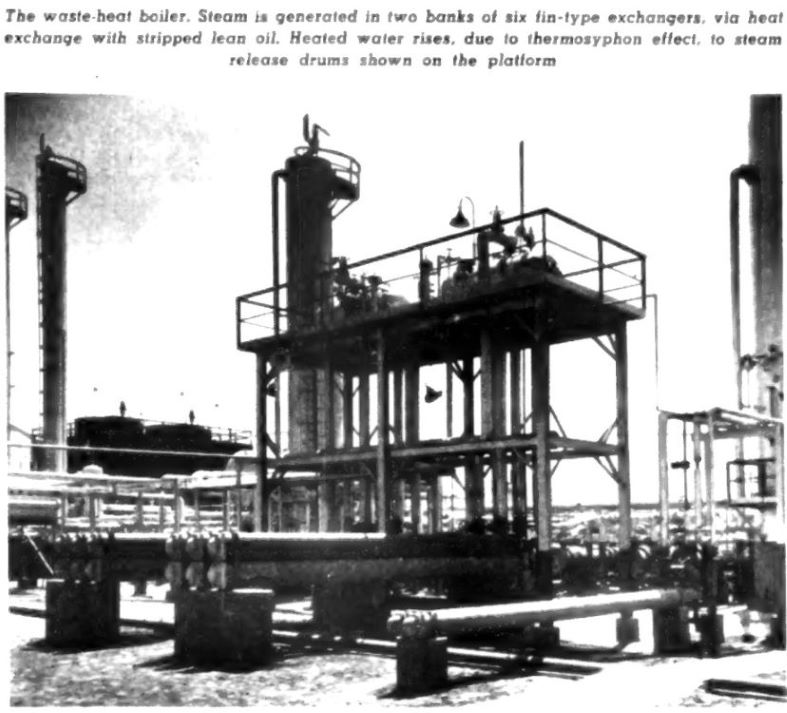

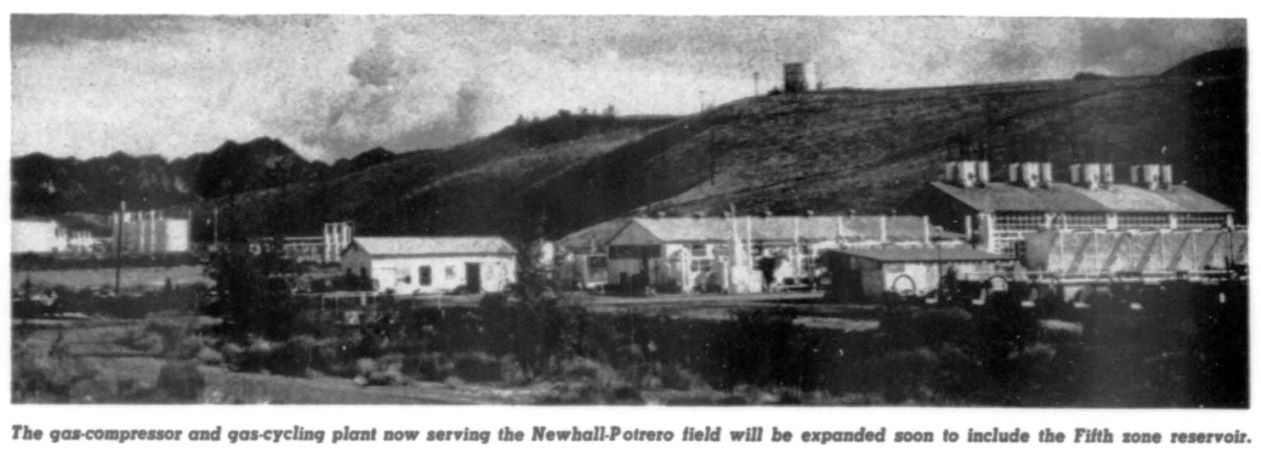

Below are some images of the plant from various gas and oil journals of the time.

From Oil & Gas Journal, December 1, 1949.

From Oil & Gas Journal, June 9, 1949.

From Oil & Gas Journal, June 9, 1949.

From Oil & Gas Journal, December 1, 1949.

From Oil & Gas Journal, December 1, 1949.

From Oil & Gas Journal, July 12, 1951.

From the Newhall Signal, December 21, 1973.

From California Oil World, November, 1949, Vol. 42 No. 21.

From California Oil World, November, 1949, Vol. 42 No. 21.