Elsmere Canyon and Tunnel Area Well Abandonment 2011-2012

At well Sewell & Jones 11 - Partially hidden coiled tube rig showing the injector head with a curved guide beam on top called a gooseneck. The coiled tube reel can be seen in the background.

During late December of 2011 and early January of 2012 plugging and abandonment operations were performed on five wells in the Elsmere Canyon and Tunnel areas. They were all last owned by the Sewell & Jones Company and are now owned by the consortium that owns Elsmere Canyon, which includes the Santa Monica Mountains Conservancy. This work was suggested by the DOGGR and agreed upon by the consortium. The wells were deserted by Sewell & Jones and never legally plugged and abandoned. DOGGR contracted with Excalibur Well Services Corporation to do the work.

The wells plugged were Sewell & Jones 8 (Elsmere oil field), Sewell & Jones 11 (Elsmere oil field), Sewell & Jones 12 (Elsmere oil field), Commercial 1 (Tunnel Area oil field), and Squaw Flat 1 (Tunnel Area oil field). See my Elsmere Canyon and Tunnel Area oil history pages for more information on these wells.

Leah Clampitt Sewell (1907 - 1968) and Barbara Clampitt Jones (1911 - 1984) were the daughters of Edward A. Clampitt (1869 - 1919). E.A. Clampitt was the owner of the wells. The daughters, along with his wife Margaret (1871 - 1928), inherited his oil property when he died. He owned scores of wells in Los Angeles and Kern counties. The Clampitt daughters first appeared as a company together in Division of Oil and Gas records of 1930.

All these wells were available for inspection by hikers. None were leaking oil. However, at least one well was plugged with debris near the surface causing underground gas pressure to build up, a potentially dangerous situation. These five wells were obviously historic and all but one are now hidden below ground level. That has to be considered a loss to the community.

MRCA Ranger Tony first gave me a heads up that this work was going to be done. Bruce Hesson of the DOGGR, provided me with some of the dates that the work was being done enabling me to be in the area to take some photos. Bruce also explained some of the procedures that were being done to do the plugging and abandonment work. The Excalibur cleanup crew were also very friendly and helpful to me while they were removing the old pipes and junk that had accumulated up over the years. Thanks to all.

Any errors that follow are naturally mine.

Well Abandonment:

California law requires that all wells that are no longer needed be properly plugged and abandoned. A well is no longer needed when it is either dry (no oil or gas found) or the oil or gas reservoir becomes depleted. The Division of Oil, Gas & Geothermal Resources is responsible for enforcing the regulations pertaining to the drilling, operation, maintenance and abandonment of all oil and gas wells in California.

The purpose of abandonment is to prevent physical hazards, prevent a pollution entrance, and to prevent the intermixing of aquifer layers (or to prevent vertical fluid migration in the borehole).

A well is plugged by placing cement in the borehole or casing at certain intervals (specified by laws or regulations). Cement plugs are required to be placed across the oil or gas reservoir (zone plug), across the base of fresh water (BFW plug), and at the surface (surface plug). Other cement plugs may be required at the bottom of a string of open casing (shoe plug), on top of tools that have become stuck in the hole (junk plug), on top of cut casing (stub plug), or anywhere else where a cement plug may be needed. The length required for each plug will vary. Also, the hole may be filled with drilling mud to help prevent the migration of fluids. Completely filling the well hole with cement is costly and unnecessary. When plugging has been completed, the surface around the wellhead is normally excavated to some depth (typically from 1 to 5 feet), the wellhead and casing are cut off, and a cap with the API well number is welded over the end of the casing. The hole is then buried and the well site is restored.

Plugging and abandonment operations must be witnessed, and bought off by, a DOGGR engineer.

More well abandonment information can be found here (PDF 600KB).

Coil Tubing:

Abandonment operations were performed by a coil tubing unit. A coil tubing unit is a self contained multi-use machine that can just about do anything a conventional service rig can do. It is more cost effective and time effective for well intervention operations, of which well abandonment is one.

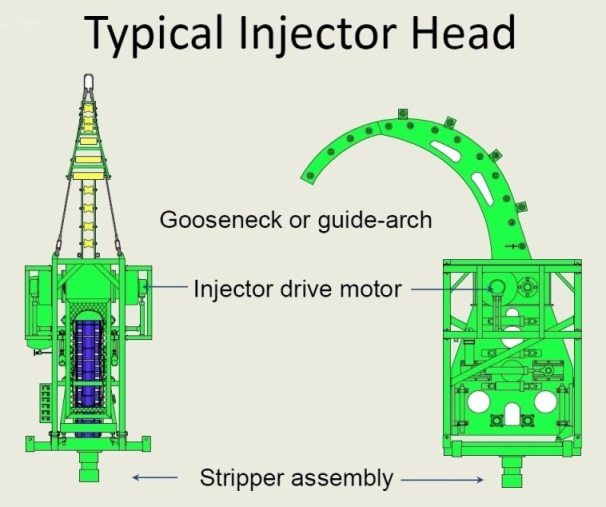

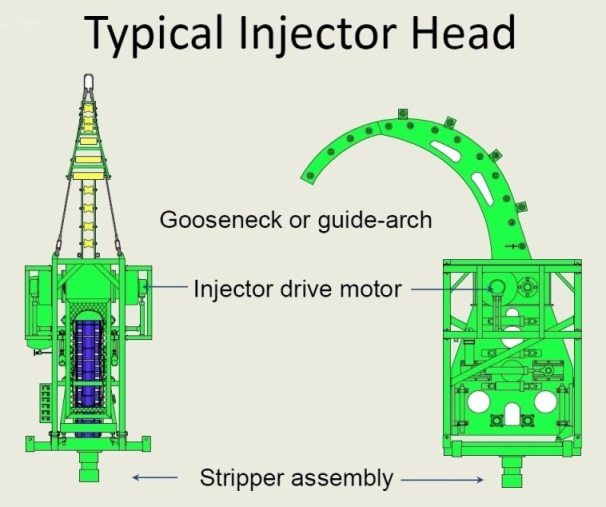

Coiled tubing (CT) is a continuous length of small diameter (1 to 4 1/2 inches) flexible steel tubing. It is spooled on a reel for storage and transport. The bigger the diameter, the deeper it can be used, but the more it weighs. A hydralic power pack controlled from a console on the truck drives the injector head. The tubing passes over a gooseneck and through an injector. The injector pushes or pulls the coiled tubing into or out of the well hole. The CT can be uncoiled in the well and returned back to the reel up to 50 or more times before metal fatigue forces its retirement.

More CT information can be found here (PDF 1.2MB).

Notes:

CalGem: California Energy Management Division (formerly the Division of Oil, Gas, and Geothermal Resources)

API: American Petroleum Institute

Zonite: Zonite is form of highly compressed sodium bentonite that is used to seal holes. Bentonite is a type of impure clay. Clay typically expands when wet. The borehole is filled with water to the desired depth and the dry Zonite is dumped into the well. The Zonite expands to form a very effective impermeable barrier (or plug).

Cement: Cements are categorized according to an American Petroleum Institute (API) specification. There are 8 classes of cement according to the depth of the well, the temperature, and the pressure. Some of the classes have been dropped since the specification was defined. The three most commonly used oil well cement types are Class A, Class G and Class H. Class A is used in milder, less demanding well conditions, while Classes G and H are specified for deeper, hotter and higher pressure well conditions.

Tag: This means to touch an object downhole (like the top of cement) with the drill stem to measure how deep it is. You will often see this in abandonment reports.